32

Model C712

Operating Procedures

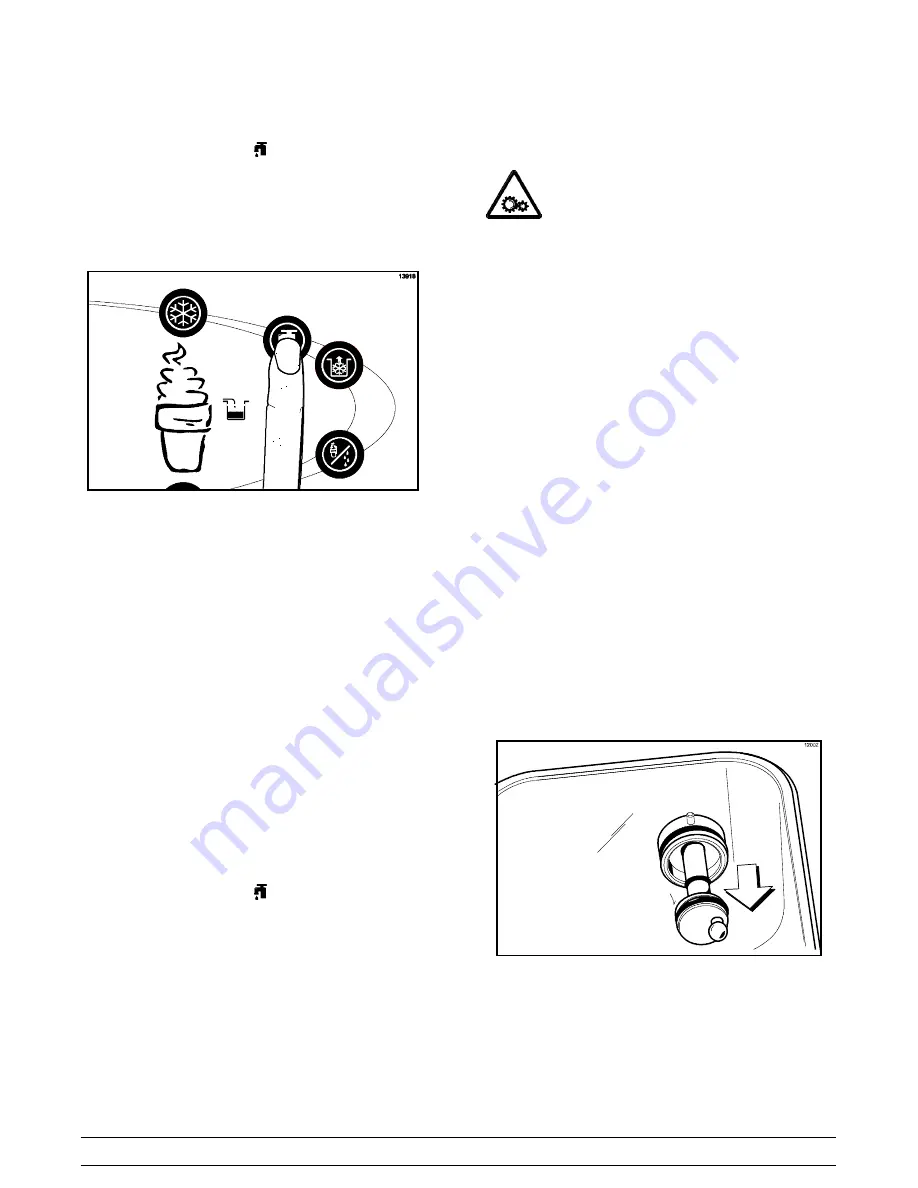

Step 4

Touch the WASH symbol

. This will cause the

cleaning solution in the freezing cylinder to come in

contact with all areas of the freezing cylinder. Wait

at least 5 minutes before proceeding with these

instructions. (See Figure 67.)

Figure 67

Step 5

Place an empty pail beneath the door spouts.

Step 6

Raise the prime plug.

Step 7

When a steady stream of cleaning solution is flowing

from the prime plug opening in the bottom of the

freezer door, open the draw valve. Draw off all the

solution.

Step 8

Once the cleaning solution stops flowing from the

door spout, close the draw valve and the prime plug.

Step 9

Touch the WASH symbol

, cancelling the Wash

mode.

Repeat these steps on the other side of the

machine.

Disassembly

MAKE SURE THE POWER SWITCH IS IN

THE “OFF” POSITION!

Failure to follow this

instruction may result in severe personal injury from

hazardous moving parts.

Step 1

Remove the handscrews, freezer door, beater and

scraper blades, and drive shaft with drive shaft seal

from the freezing cylinder.

Step 2

Remove the scraper blade clips from the scraper

blades.

Step 3

Remove the drive shaft seal from each drive shaft.

Step 4

From each pump cylinder, remove the retaining pin,

mix inlet adaptor, valve cap, pump gasket, and the

piston. Remove the o-ring from the piston and valve

cap.

Step 5

Remove the freezer door gaskets, front bearings,

pivot pin, draw handles, draw valves, prime plugs,

and design caps. Remove the o-rings from the draw

valves.

Step 6

Remove the pump drive shafts from the drive hubs

in the rear wall of the mix hoppers. (See Figure 68.)

Figure 68

Summary of Contents for C712

Page 54: ...Model C712 059898 27 5 13 ...

Page 55: ...Model C712 059898 33 5 13 ...

Page 56: ...Model C712 059898 40 5 13 ...

Page 57: ...Model C712 059898 58 5 13 ...