5-4

USER INTERFACE

087482-M

User Interface

5

Feed Tube

The feed tube maintains over-run and allows enough mix

to enter the freezing cylinder after a draw. One end of the

tube has a mix delivery hole on the side, and the other

end does not.

Figure 5-4

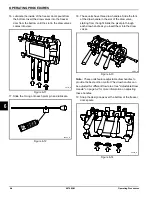

The feed tube serves two purposes.

•

Normal Operation:

After priming the machine, the

end of the feed tube with the mix delivery hole is

placed in the mix inlet hole, and the air orifice is

installed. Every time the draw handle is raised, new

mix and air from the hopper will flow down into the

freezing cylinder. This will keep the freezing cylinder

properly loaded and will maintain overrun.

Figure 5-5

•

Standby Operation:

During long “no sale” periods,

the air orifice is removed and the feed tube is

inverted. The end of the feed tube without the mix

delivery hole is placed in the mix inlet hole to prevent

mix from entering the freezing cylinder.

Figure 5-6

Note:

Make sure the level of mix is below the mix

delivery hole in the side of the feed tube. Failure to follow

this instruction may result in lower product quality when

normal operation is resumed.

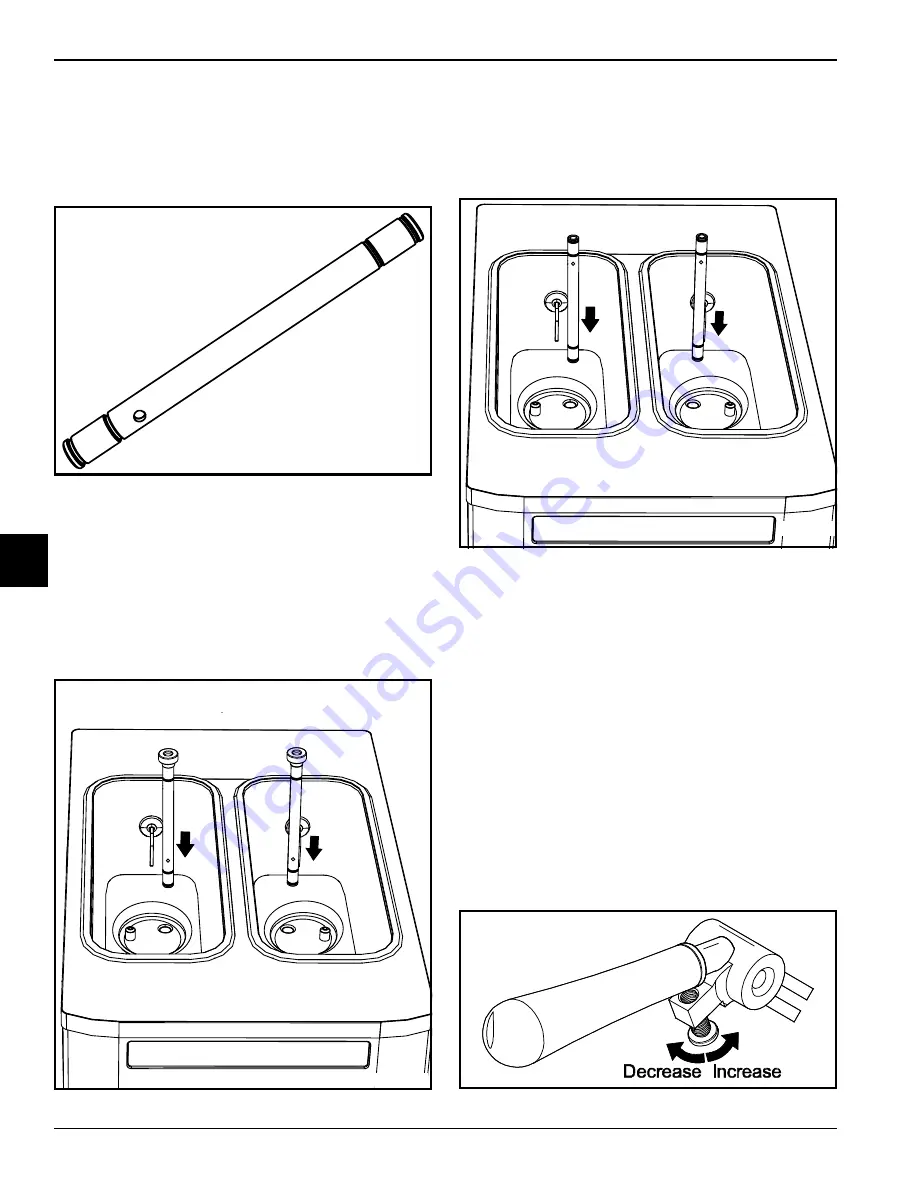

Adjustable Draw Handle

These units feature an adjustable draw handle to provide

the best portion control, giving a better, consistent quality

to your product and controlling costs. The draw handle

should be adjusted to provide a flow rate of 5 oz. to

7-1/2 oz. (142 g to 213 g) of product by weight per 10

seconds. To

increase

the flow rate, tighten the screw. To

decrease

the flow rate, loosen the screw.

Important!

When dispensing product, pull only one draw

handle at a time.

Figure 5-7

30124

30123

30121

Summary of Contents for C791

Page 8: ...1 4 TO THE INSTALLER 087482 M To the Installer 1 ...

Page 38: ...9 2 PARTS REPLACEMENT SCHEDULE 087482 M Parts Replacement Schedule 9 Notes ...

Page 42: ...10 4 LIMITED WARRANTY ON EQUIPMENT 087482 M Limited Warranty on 10 Notes ...

Page 46: ...11 4 LIMITED WARRANTY ON PARTS 087482 M Limited Warranty on Parts 11 Notes ...