24

Models 8752, 8756, 8757

Operating Procedures

150422

Air/Mix Pump Assembly

The purpose of the air/mix pump is to meter a specific

amount of air and mix and transfer this combination to

the freezing cylinder.

Refer to the illustration on page 28 for identification of

parts during assembly.

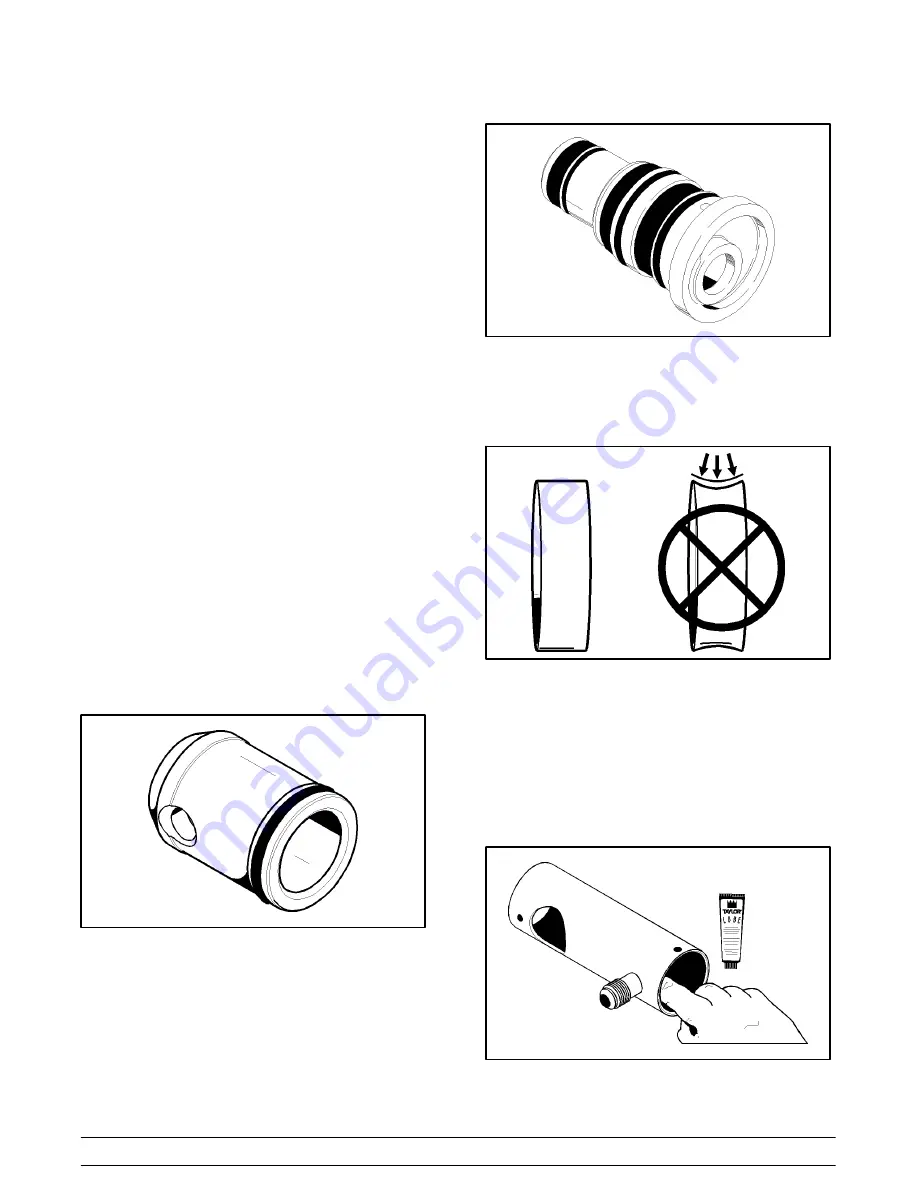

Step 1

Inspect the rubber and plastic pump parts. The

o

−

rings, check ring, and gasket must be in 100% good

condition for the pump and entire machine to operate

properly. They cannot properly serve their intended

function if nicks, cuts, or holes in the material are

present.

Inspect the plastic pump parts for cracks, wear, and

de

−

lamination of plastic.

Replace any defective parts immediately and discard

the old.

Step 2

Assemble the piston. Slide the o

−

ring into the groove

on the piston.

DO NOT

lubricate this o

−

ring.

Figure 24

Step 3

Assemble the liquid valve body. Slide the three check

bands and three o

−

rings into the grooves on the liquid

valve body.

DO NOT

lubricate the check bands or

o

−

rings.

Figure 25

Note:

Check bands have two smooth surfaces. A

concave shape indicates an incorrect assembly. Turn

the check band inside out to correctly expose the flat

surface.

Figure 26

Step 4

Put a small amount of lubricant inside the piston and

insert the liquid valve body into the piston.

Apply a small amount of lubricant to the

lower

inside

diameter of the pump cylinder to a depth equivalent to

the length of your index finger. Once applied, the

amount of lubricant should be equal to a paper

−

thin

film.

Figure 27