6-8

OPERATING PROCEDURES

Model 8756

Operating Procedures

6

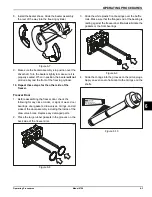

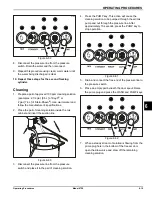

9. Slide the O-ring into the groove on the mix inlet fitting

and lubricate the O-ring.

Figure 6-30

10. Insert the mix inlet fitting into the hole in the base of

the liquid valve body.

Figure 6-31

11. Secure the pump parts by sliding the keeper pin

through the holes at the bottom of the pump body.

Figure 6-32

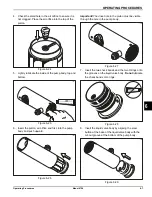

12. Assemble the flare line and suction line. Attach the

suction line to the barbed end of the mix inlet fitting

and allow the weighted end to hang freely.

Attach one end of the flare line to the threaded fitting

on the lower side of the pump body. Allow the other

end to hang freely.

Figure 6-33

13. Place the pump collar over the pump body.

Note:

The crossholes of the pump collar will be on top.

Figure 6-34

15047

Apply the appropriate

Taylor approved food safe lubricant.

15048

15049

15097

15022

Summary of Contents for Horizon 8756

Page 18: ...4 6 OPERATOR PARTS IDENTIFICATION Model 8756 Operator Parts Identification 4 Notes ...

Page 22: ...5 4 USER INTERFACE Model 8756 User Interface 5 Notes ...

Page 40: ...6 18 OPERATING PROCEDURES Model 8756 Operating Procedures 6 Notes ...

Page 46: ...8 4 TROUBLESHOOTING GUIDE Model 8756 Troubleshooting Guide 8 Notes ...

Page 48: ...9 2 PARTS REPLACEMENT SCHEDULE Model 8756 Parts Replacement Schedule 9 Notes ...

Page 52: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model 8756 Limited Warranty on Equipment 10 Notes ...

Page 56: ...11 4 LIMITED WARRANTY ON PARTS Model 8756 Limited Warranty on Parts 11 Notes ...

Page 58: ...12 2 WIRING DIAGRAMS Model 8756 Wiring Diagrams 12 Notes ...