OPERATING PROCEDURES

6-9

Model 8756

Operating Procedures

6

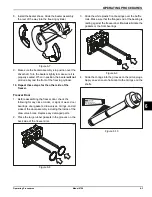

14. Align the drive hole in the piston to the ball crank of

the motor reducer. Simultaneously, align the locating

pin on the face plate.

Slide the pump collar upward into the grooves on the

side of the face plate and secure the air/mix pump in

place by slipping the keeper pin through the

crossholes of the pump collar.

Important!

Alignment of the air/mix pump is

extremely important. Severe and costly damage may

occur when it is not properly aligned.

Figure 6-35

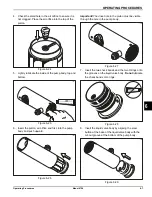

15. Lubricate both sides of the pressure switch

diaphragm.

Figure 6-36

16. Place diaphragm into groove of the pressure switch

cap.

Figure 6-37

17. Screw the cap securely onto the housing.

Figure 6-38

Note:

Repeat these steps for other the side of freezer.

Sanitizing

1. Prepare a pail of approved 100 ppm sanitizing

solution (examples: 2-1/2 gal. [9.5 L] of Kay-5

®

or

2 gal. [7.6 L] of Stera-Sheen

®

). Use warm water and

follow the manufacturer's specifications.

2. Place the pail of sanitizing solution inside the mix

cabinet.

15055

15056

Apply the appropriate

Taylor approved food safe lubricant.

15057

15058

Summary of Contents for Horizon 8756

Page 18: ...4 6 OPERATOR PARTS IDENTIFICATION Model 8756 Operator Parts Identification 4 Notes ...

Page 22: ...5 4 USER INTERFACE Model 8756 User Interface 5 Notes ...

Page 40: ...6 18 OPERATING PROCEDURES Model 8756 Operating Procedures 6 Notes ...

Page 46: ...8 4 TROUBLESHOOTING GUIDE Model 8756 Troubleshooting Guide 8 Notes ...

Page 48: ...9 2 PARTS REPLACEMENT SCHEDULE Model 8756 Parts Replacement Schedule 9 Notes ...

Page 52: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model 8756 Limited Warranty on Equipment 10 Notes ...

Page 56: ...11 4 LIMITED WARRANTY ON PARTS Model 8756 Limited Warranty on Parts 11 Notes ...

Page 58: ...12 2 WIRING DIAGRAMS Model 8756 Wiring Diagrams 12 Notes ...