6-16

OPERATING PROCEDURES

Model 8756

Operating Procedures

6

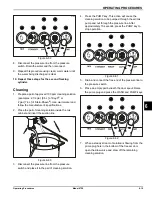

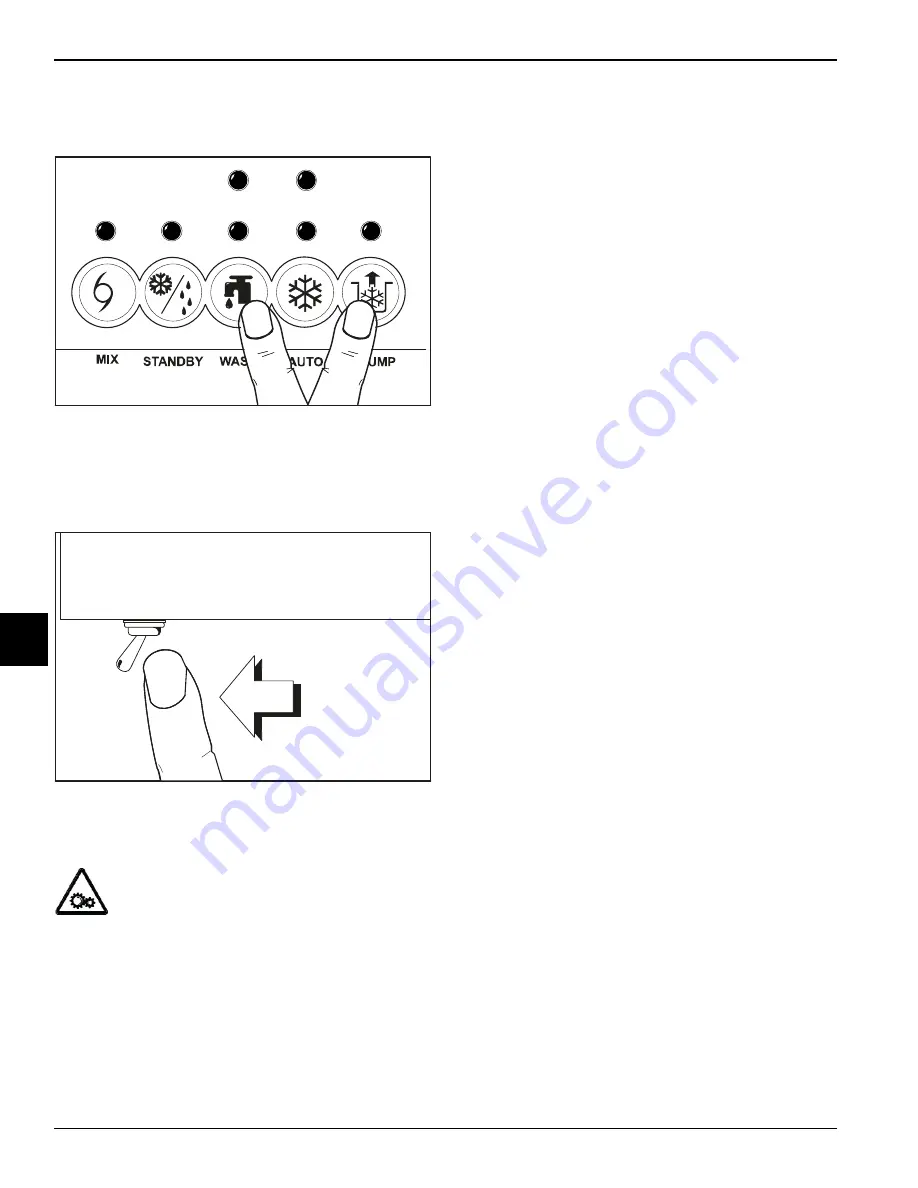

8. Once the solution stops flowing from the door spout,

close the draw valve and press the WASH and

PUMP keys to stop operation.

Figure 6-63

9. Repeat these steps for the other side of the

freezer.

10. Place the power switch in the OFF position before

disassembling the machine.

Figure 6-64

Disassembly

WARNING!

Make sure the power switch is in

the OFF position. Failure to follow this instruction may

result in severe personal injury from hazardous moving

parts.

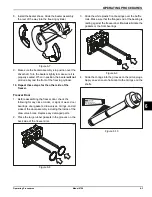

1. Remove the handscrews, freezer door, beaters,

shoes, scraper blades, and driveshafts from the

freezing cylinders. Take these parts to the sink for

cleaning.

2. Remove the air/mix pump. Unscrew the flare line

from the mix inlet tube. Disengage the pressure line

from the pressure switch and the mix inlet tube. Pull

the retaining pin out of the pump collar and slide the

collar down. Tilt the air/mix pump away from the

machine and take the entire assembly to the sink for

further disassembly and brush-cleaning.Take these

parts to the sink for cleaning.

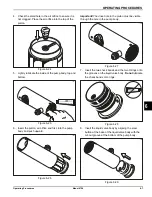

3. Remove the pressure switch cap from the mix

cabinet. Remove the diaphragm from the cap.

4.

Repeat steps 3 and 4 for the other side of the

freezer.

5. Remove the front drip tray and the splash shield.

Brush-Cleaning

1. Prepare a sink with an approved cleaning solution

(examples: Kay-5

®

or Stera-Sheen

®

). Use warm

water and follow the manufacturer's specifications.

If an approved cleaner other than Kay-5® or

Stera-Sheen

®

is used, dilute it according to the label

instructions.

Important!

Follow the label directions. Too

strong

of

a solution can cause parts damage, and too

mild

of a

solution will not provide adequate cleaning. Make

sure all brushes provided with the freezer are

available for brush-cleaning.

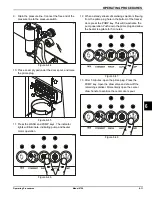

2. Remove the seals from the driveshafts.

3. Remove the following from the freezer doors:

gaskets, front bearings, pivot pins, draw handles,

draw valves, prime plugs, and design caps. Remove

all O-rings.

Note:

To remove the O-rings, use a single-service

towel to grasp the O-ring. Apply pressure upward

until the O-ring pops out of its groove. With the other

hand, push the top of the O-ring forward. It will roll

out of the groove and can be easily removed. If there

is more than one O-ring to be removed, always

remove the rear O-ring first. This will allow the O-ring

to slide over the forward rings without falling into the

open grooves.

13038wp

13003

Summary of Contents for Horizon 8756

Page 18: ...4 6 OPERATOR PARTS IDENTIFICATION Model 8756 Operator Parts Identification 4 Notes ...

Page 22: ...5 4 USER INTERFACE Model 8756 User Interface 5 Notes ...

Page 40: ...6 18 OPERATING PROCEDURES Model 8756 Operating Procedures 6 Notes ...

Page 46: ...8 4 TROUBLESHOOTING GUIDE Model 8756 Troubleshooting Guide 8 Notes ...

Page 48: ...9 2 PARTS REPLACEMENT SCHEDULE Model 8756 Parts Replacement Schedule 9 Notes ...

Page 52: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model 8756 Limited Warranty on Equipment 10 Notes ...

Page 56: ...11 4 LIMITED WARRANTY ON PARTS Model 8756 Limited Warranty on Parts 11 Notes ...

Page 58: ...12 2 WIRING DIAGRAMS Model 8756 Wiring Diagrams 12 Notes ...