OPERATING PROCEDURES

6-17

Model 8756

Operating Procedures

6

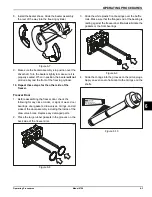

4. Remove the flare lines, suction lines, retaining pins,

and mix inlet fittings from the pump cylinders.

Remove the liquid valve bodies from the pump

cylinders. Remove the pistons from the pump

cylinders. Remove all O-rings and check bands.

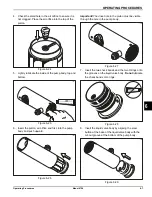

5. Use a small amount of cleaning solution and the

black bristle brush to brush-clean the rear shell

bearings at the back of the freezing cylinders.

Figure 6-65

Important!

Cleaning the tubes requires special attention

because bacteria and milkstone can build up here.

6. Use the long, flexible brush and cleaning solution to

clean the mix inlet tubes in the mix cabinet.

Thoroughly clean the tubes all the way up to the

freezing cylinder.

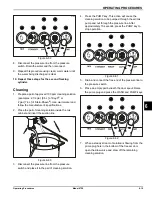

7. Remove the rear drip pan from the side panel and

take it to the sink for cleaning.

Note:

If the rear drip pan is filled with an excessive

amount of mix, refer to the Troubleshooting Guide.

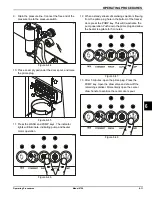

8. Thoroughly brush-clean all disassembled parts in the

cleaning solution. Make sure all lubricant and mix film

is removed. Take particular care to brush-clean the

draw valve cores in the freezer door.

9. Place the parts on a clean, dry surface to air-dry

overnight.

10. Wipe clean all exterior surfaces of the freezer and the

mix cabinet.

11439

Summary of Contents for Horizon 8756

Page 18: ...4 6 OPERATOR PARTS IDENTIFICATION Model 8756 Operator Parts Identification 4 Notes ...

Page 22: ...5 4 USER INTERFACE Model 8756 User Interface 5 Notes ...

Page 40: ...6 18 OPERATING PROCEDURES Model 8756 Operating Procedures 6 Notes ...

Page 46: ...8 4 TROUBLESHOOTING GUIDE Model 8756 Troubleshooting Guide 8 Notes ...

Page 48: ...9 2 PARTS REPLACEMENT SCHEDULE Model 8756 Parts Replacement Schedule 9 Notes ...

Page 52: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model 8756 Limited Warranty on Equipment 10 Notes ...

Page 56: ...11 4 LIMITED WARRANTY ON PARTS Model 8756 Limited Warranty on Parts 11 Notes ...

Page 58: ...12 2 WIRING DIAGRAMS Model 8756 Wiring Diagrams 12 Notes ...