8-2

TROUBLESHOOTING GUIDE

Model 8756

Troubleshooting Guide

8

3. Product is too stiff.

a. Insufficient mix in the freezing

cylinder.

a. Refer to problem #2.

- - -

b. Improper priming procedures.

b. Drain the freezing cylinder and reprime

the machine.

c. Out-of-date mix.

c. Use fresh mix.

d. Viscosity control is set too cold.

d. Contact a Taylor service technician.

- - -

4. Product is too soft.

a. Worn scraper blades.

a. Replace scraper blades regularly.

b. Dirty condensers or air filters on

air-cooled machines.

b. Clean monthly.

c. Inadequate water supply on

water-cooled machines.

c. Check the water supply. Check water

lines for leaks or kinks.

d. Inadequate airspace around

air-cooled machines.

d. Allow adequate room for airflow across

the condensers. Minimum of

3 in. (76 mm) clearance on all sides. Do

not obstruct the air discharge on top.

Provide 12 in. (305 mm) clearance on

top of freezer.

e. Viscosity control is set too warm.

e. Contact a Taylor service technician.

- - -

5. Mix in the mix cabinet is

too warm.

a. Warm mix was placed in the tank.

a. Mix added to the mix tank should be

below 40°F (4.4°C).

b. The mix cabinet door was left open.

b. The door must be kept closed.

c. The mix cabinet door gasket is not

sealing.

c. Repair or replace gasket.

- - -

d. Dirty mix cabinet condenser or air

filter.

d. Clean monthly.

e. The mix cabinet refrigeration

system needs adjustment.

e. Contact a Taylor service technician.

- - -

6. Mix in the mix cabinet is

too cold.

a. The mix cabinet refrigeration

system needs adjustment.

a. Contact a Taylor service technician.

- - -

7. Excessive mix leakage

from the bottom of the

door spout.

a. Worn, missing, or incorrect O-ring

on the draw valve.

a. Check the O-rings.

(Replace every 3 months.)

b. Improper lubrication on the draw

valve O-rings.

b. Lubricate properly.

8. Excessive mix leakage

into the rear drip pan.

a. Worn or missing driveshaft seal.

a. Install or replace the seal.

b. Improper lubrication of the

driveshaft.

b. Lubricate properly.

c. Worn rear shell bearing.

c. Contact a Taylor service technician to

replace the rear shell bearing.

- - -

d. The gearbox is out of alignment.

d. Contact a Taylor service technician to

align the gearbox.

- - -

9. The driveshaft is stuck in

the gearbox coupling.

a. Rounded corners on hex end of

driveshaft or gear coupling.

a. Replace damaged component.

- - -

b. The gearbox is out of alignment.

b. Contact a Taylor service technician to

align the gearbox.

- - -

Problem

Probable Cause

Remedy

Page

Ref.

Summary of Contents for Horizon 8756

Page 18: ...4 6 OPERATOR PARTS IDENTIFICATION Model 8756 Operator Parts Identification 4 Notes ...

Page 22: ...5 4 USER INTERFACE Model 8756 User Interface 5 Notes ...

Page 40: ...6 18 OPERATING PROCEDURES Model 8756 Operating Procedures 6 Notes ...

Page 46: ...8 4 TROUBLESHOOTING GUIDE Model 8756 Troubleshooting Guide 8 Notes ...

Page 48: ...9 2 PARTS REPLACEMENT SCHEDULE Model 8756 Parts Replacement Schedule 9 Notes ...

Page 52: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model 8756 Limited Warranty on Equipment 10 Notes ...

Page 56: ...11 4 LIMITED WARRANTY ON PARTS Model 8756 Limited Warranty on Parts 11 Notes ...

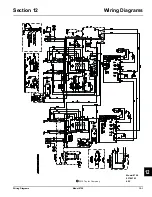

Page 58: ...12 2 WIRING DIAGRAMS Model 8756 Wiring Diagrams 12 Notes ...