6-6

OPERATING PROCEDURES

Model 8756

Operating Procedures

6

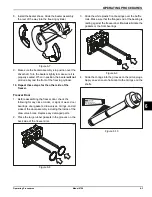

6. Insert the rear drip pan into the opening on the side

panel.

Figure 6-19

7. Install the front drip tray and the splash shield under

the door spouts.

Figure 6-20

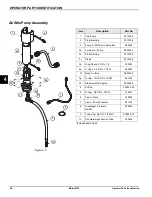

Air/Mix Pump Assembly

This model uses a single-stage pump to transfer specific

amounts of air and mix to the freezing cylinder.

1. Inspect the rubber and plastic pump parts. These

parts must be in 100% good condition for the pump

and the entire machine to operate properly. They

cannot properly serve their intended function when

nicks, cuts, or holes in the material are present.

Inspect the plastic pumps parts for cracks, wear, and

delamination of plastic. Replace any defective parts

immediately and discard the old.

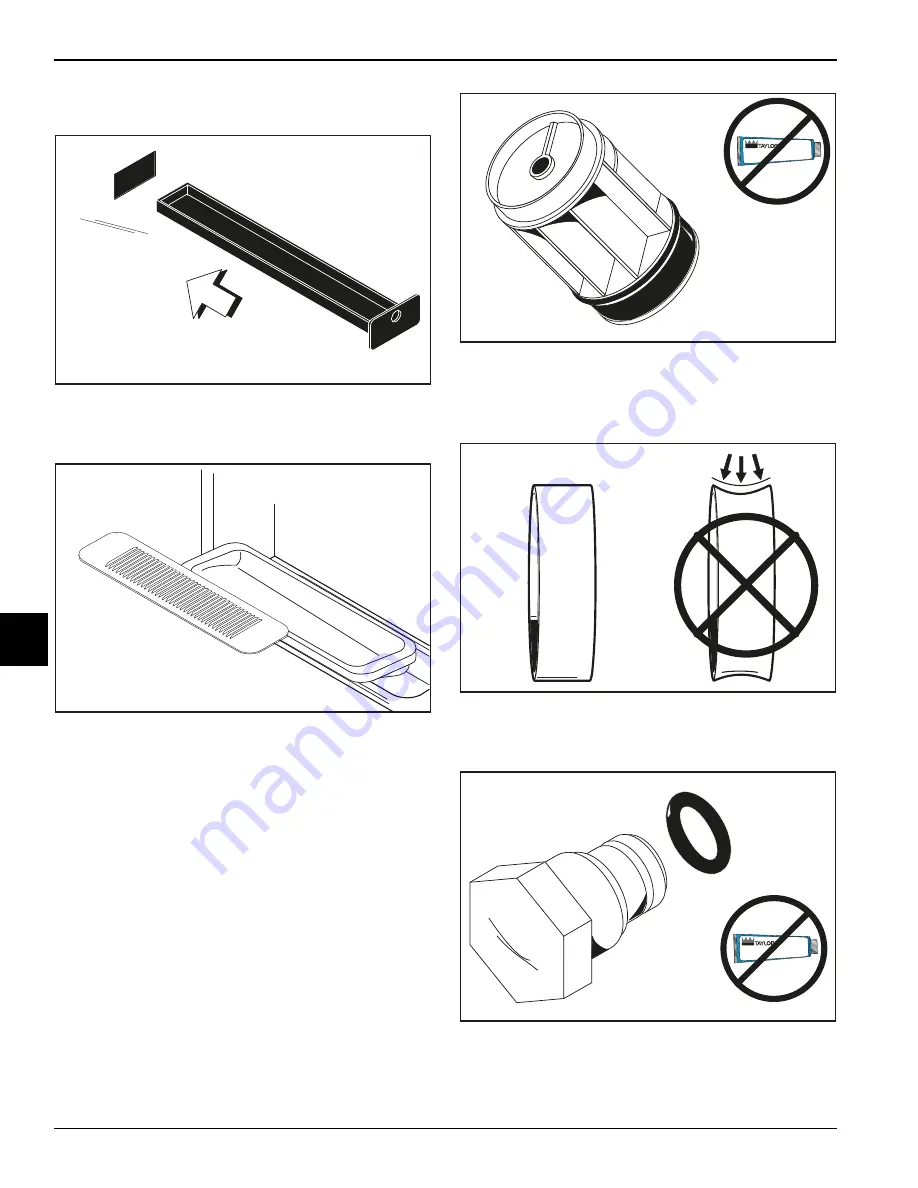

2. Assemble the piston by sliding the check band and

the O-ring into the grooves on the piston.

Do not

lubricate the check band or O-ring.

Figure 6-21

Note:

A concave check band indicates an incorrect

assembly. Turn the check band inside out to correctly

expose the flat surface.

.

Figure 6-22

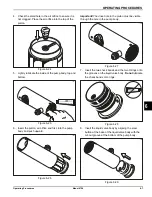

3. Install the small O-ring into the groove on the air

orifice.

Do not

lubricate this O-ring.

Figure 6-23

10176i

10338

Apply the appropriate

Taylor approved food safe lubricant.

15045

15041

Apply the appropriate

Taylor approved food safe lubricant.

15050

Summary of Contents for Horizon 8756

Page 18: ...4 6 OPERATOR PARTS IDENTIFICATION Model 8756 Operator Parts Identification 4 Notes ...

Page 22: ...5 4 USER INTERFACE Model 8756 User Interface 5 Notes ...

Page 40: ...6 18 OPERATING PROCEDURES Model 8756 Operating Procedures 6 Notes ...

Page 46: ...8 4 TROUBLESHOOTING GUIDE Model 8756 Troubleshooting Guide 8 Notes ...

Page 48: ...9 2 PARTS REPLACEMENT SCHEDULE Model 8756 Parts Replacement Schedule 9 Notes ...

Page 52: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model 8756 Limited Warranty on Equipment 10 Notes ...

Page 56: ...11 4 LIMITED WARRANTY ON PARTS Model 8756 Limited Warranty on Parts 11 Notes ...

Page 58: ...12 2 WIRING DIAGRAMS Model 8756 Wiring Diagrams 12 Notes ...