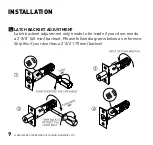

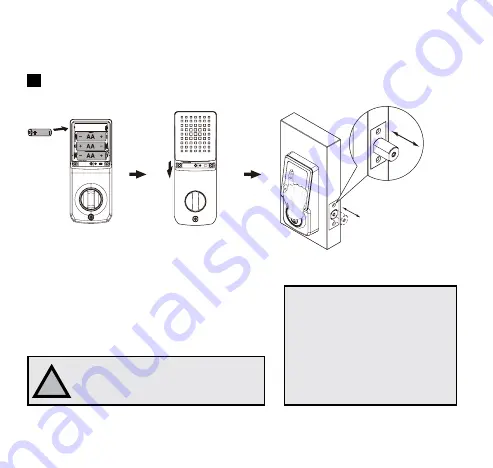

Install batteries

Install battery cover

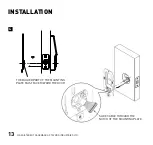

Enter default program-

ming code (12345678)

and the lock will set up

bolt direction to complete

installation.

INSTALLATION

10

19

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

Install batteries and perform automatic bolt direction determination.

CAUTION

Please use four alkaline batteries

for better performance.

!

NOTE:

1. The lockset will perform

automatic bolt direction

determination.

2. The product is ready for

use when automatic bolt

direction determination is

completed.

AA