Model LR-26C, LR-623, LR-28A, & LR-2355 Hoist Installation and Operation Manual

Stock No. 036268

Page 22 of 27

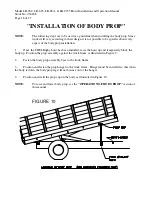

"OPERATION OF BODY PROP"

WARNING:

Being under a raised body can result in serious injury or death should the body

unexpectedly descend.

Never

position yourself or allow others to position themselves

under a

loaded

body.

Always

prop the

unloaded

body up using the body prop or body

props supplied.

Remember,

body props are to be used only on an

unloaded

body.

When two props are provided, both props must be used.

Below is a step-by-step procedure for using the body prop.

1.

Raise body to sufficient height and shut off all power.

2.

Grasp prop handle at arms length and rotate prop upwards.

3.

Swing prop up to vertical position and push down until prop locks in line with support bracket

on the body.

4.

Using inside-the-cab controls, lower body slowly until prop contacts prop cup.

CAUTION:

Do not power hoist down while on prop.

5.

To lower prop for normal operation, "reverse" the procedure of the above four steps.