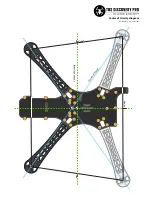

Brushless gimbal stabilization

Integrated gimbal controller

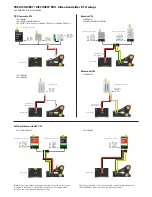

Setting up a gimbal the right way can be a daunting task, fortunately we licensed the SimpleBGC firmware

(AlexMos) and the SimpleBGC hardware layout from Viacopter. The controller has all the parameters pre-set

and gains tuned by TBS for a great out-of-the-box experience.

The gimbal controller is fully embedded into the frame (a

world's first), no soldering or software configuration

required. Just plug in the motors and IMU, and you are

good to go. The on-board USB port connects to your PC

for future firmware upgrades and custom configuration.

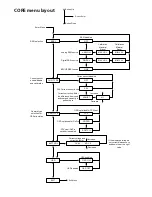

If you want to apply updates and make adjustments to

the gimbal, download the SimpleBGC and SiLabs CP210x

driver package (

www.simplebgc.com

), plug in battery

power, and connect the DISCOVERY PRO to a Windows

computer via a micro USB cable (e.g., from the NAZA-M

or a mobile phone.) Extensive details of the brushless

controller is available in the SimpleBGC manual.

DISCOVERY PRO utilizes two profiles, one silent profile (Profile 1), to keep the gimbal quiet while on ground and

one noisy profile (Profile 2). The CORE MCU will detect when main motor starts (current consumption >3A) and

switch from the silent to noisy profile automatically. If you change something in SimpleBGC you have to do the

change on both profiles. If you want to change your in-flight values you have to do this on Profile 2.

The following table shows the suggested PID and power controller gains for a GoPro HD Hero3&3+ mounted

on the gimbal. Download the factory settings from

bit.ly/tbsprosettings

.

Axis

P

I

D

Power

Poles

Inverted

FC Gain

Roll

12

0.1

9

175

14

Yes

0

Pitch

14

0.1

9

173

14

No

0

Other essential settings: Axis TOP to -Z, RIGHT to Y, skip gyro calibration at startup CHECK, gyro trust 100,

and PWM frequency to HIGH (silent) for Profile 1 and LOW for Profile 2, ROLL to RC_ROLL, PITCH to RC_PITCH,

CMD to EXT_ROLL, RC control ROLL to -30/30/CHECK/3/UNCHECK/10/0% and PITCH to

-90/90/CHECK/3/UNCHECK/10/0%.

40