TCF Termoventilatori Condizionatori Felsinea Srl

40057 Cadriano di Granarolo Emilia (Bologna), via Giuseppe di Vittorio 5

www.tcf.it

5

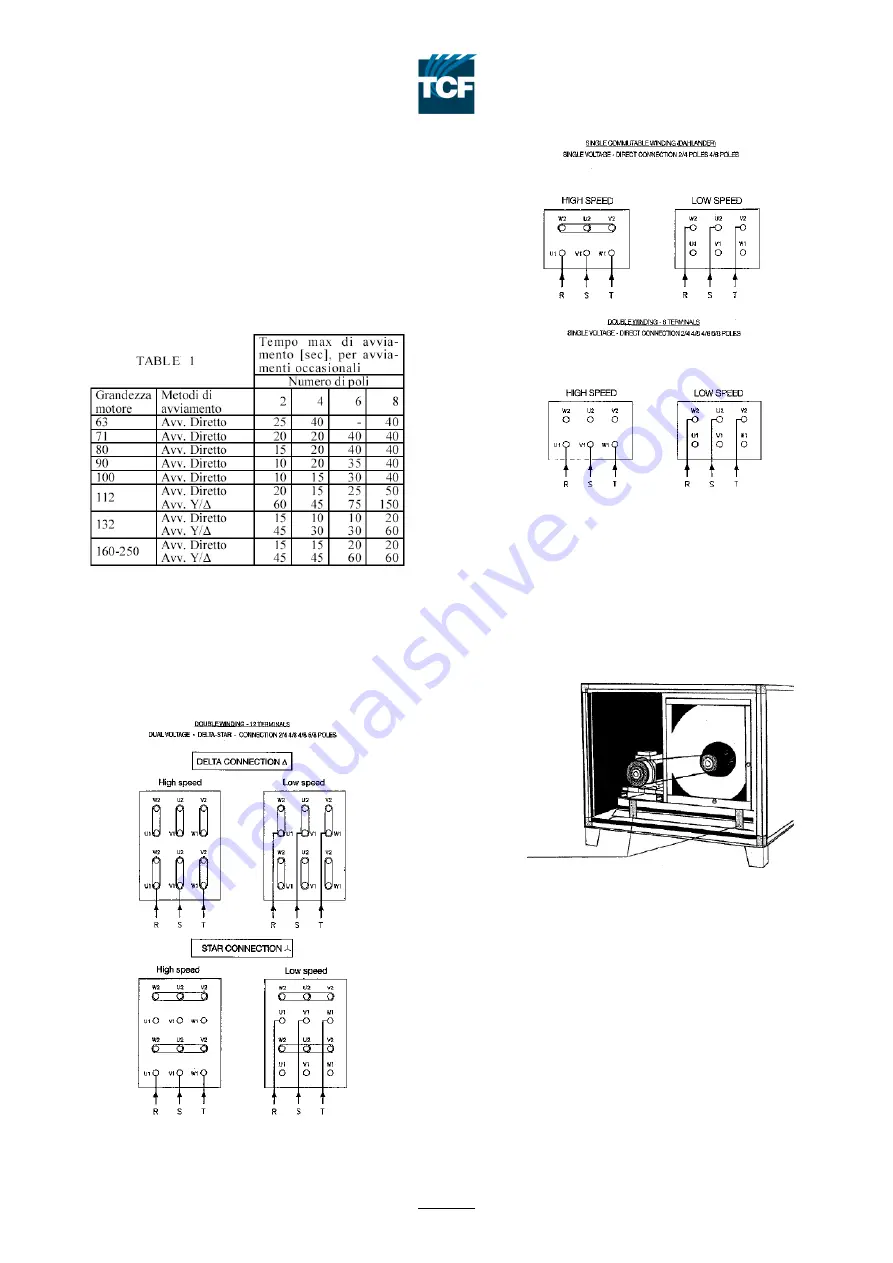

The two-speed motors with a single DAHLANDER

commutable winding (fig. 9) offer the advantage of

generating greater power than motors of the same size but

with separate windings.

4.2.1.4

Permitted start-up time

Because of the temperature increase, the start-up time of a

motor may not exceed the value shown in table 1.

The data refer to start-ups at exercise temperature, whereas

for cold start-ups such timings may be doubled.

4.2.1.5

Recommended

connection

and

protection

accessories

For the sizing of cables and connections, please refer to the

motor nameplate data and to the laws in force in the country

where the unit is installed.

FIG. 8

FIG. 9

4.2.2

Fan

Before start-up, carry out the following checks:

-

make sure that the fan wheel is functioning

correctly by rotating it manually

-

check that any safety clamp, fitted to prevent

damage during transportation, has been removed

from the dampers (fig. 10).

FIG. 10

safety clamps

4.2.3

Transmission

Before starting the air exhaust unit please check:

-

the tension of the V-belts (section 5.2.3.1)

-

that the pulleys are aligned (section 5.2.3.1)

-

that the dowels, shown in fig. 20, in their possible

installation positions, are doing their function of

securing the pulleys to the hubs