Twin City Fan & Blower Installation and Maintenance Manual: IM-495

Electrical Wiring of Fans

The customer is required to investigate and install equipment

in compliance with all local electrical and safety codes for the

equipment location. Twin City Fan & Blower requires all power

cabling be located away from the rotating impeller and fastened

to the inside of the fan housing. Wiring must be routed away from

the motor to reduce potential contact with hot or greasy surfaces.

When a fan is supplied with an outlet damper, wiring the electrical

supply to the motor requires routing the supply through the damper

housing frame. Knockouts of various sizes are provided in the damper

housing frame to accommodate cable connectors or raceway.

Fan Operation - Safety

For general safety practices for air moving equipment, see AMCA

Catalog 410.

Twin City Fan & Blower has many safety accessories available.

These safety devices include (but are not limited to) inlet and

discharge screens. The use, abuse or non-use of safety devices is

the responsibility of the purchaser.

Facility-related safety conditions include fan accessibility and

location. How easily can non-service personnel access the unit? Is

the fan in a hazardous duty environment? Was the unit ordered for

this duty? Other concerns must also be addressed. All fans should

be powered through switches, which are easily accessible to service

personnel from the fan. Every switch should have the ability to be

“locked-off” by the service person and the key to be retained by

this person to prevent accidental power of the fan while service is

in process.

Operation Check List

Check fan mechanism components:

□ System connections are properly made and tightened.

□ Bearings are properly lubricated.

□ Impeller, drives and fan surfaces are clean and free of debris.

□ Rotate the impeller by hand to verify it has not shifted in transit.

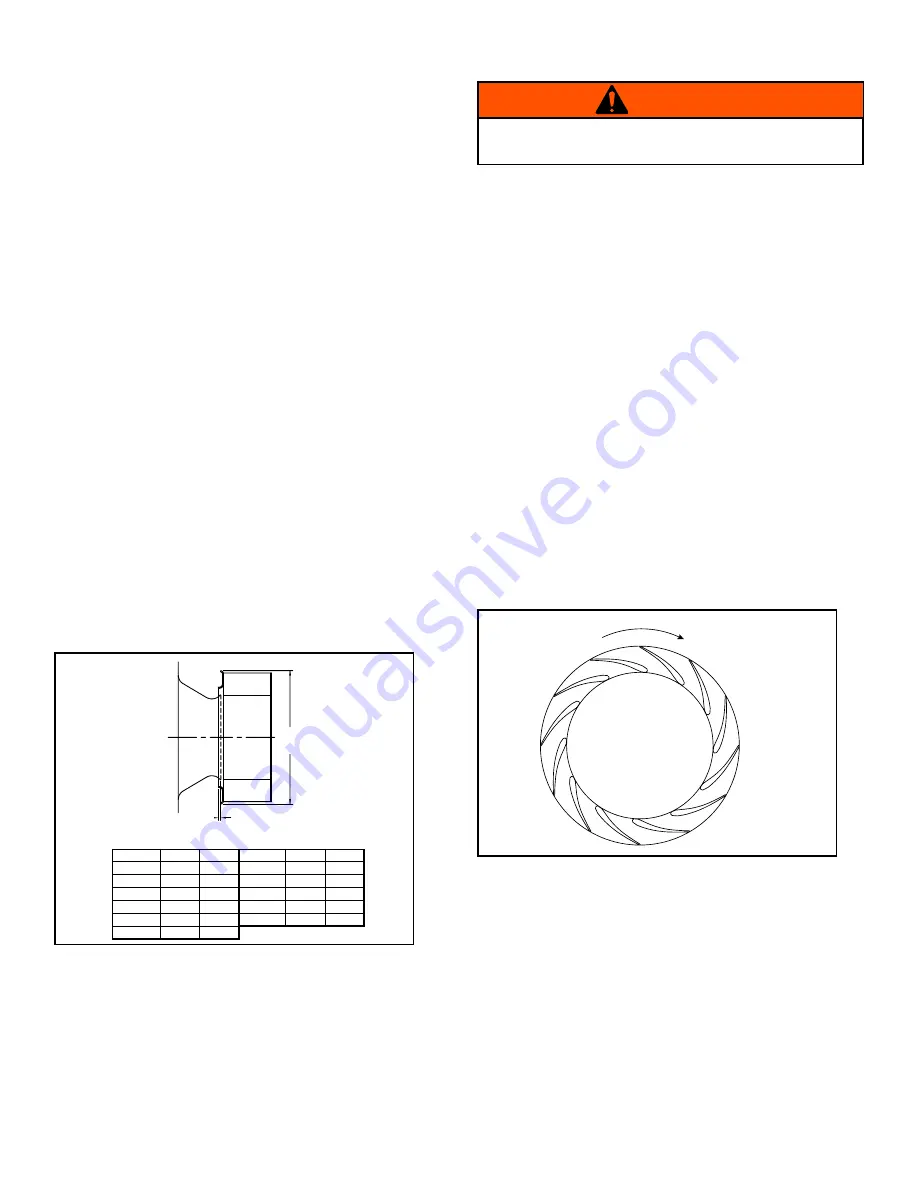

□ Check fan/impeller overlap. (See Figure 4.)

Check fan electrical components:

□ Motor is wired for proper supply voltage.

□ Motor was properly sized for power and rotational inertia of

rotating assembly.

□ Motor is properly grounded.

□ All leads are properly insulated.

Trial “bump”:

□ Turn on power just long enough to start assembly rotating.

□ Check rotation for agreement with rotation arrow.

Does the assembly make any unusual noise? (See Figure 5.)

□ Correct any problems that may have been found.

(Follow safety guidelines - shut power off.) Perform checklist

again until unit is operating properly.

□ Run unit up to speed.

Verify fastener tightness. These may have loosened during

shipment or installation.

□ Set screws attaching impeller hub to shaft.

□ Nuts on inlet funnel.

□ Nuts and bolts holding motor.

□ Nuts holding housing frame to base and base to ground.

□ Bolts in taper-lock bushings.

□ Grease line connections.

After one week of operation, check all nuts, bolts and set screws

and tighten if necessary.

A

DIA

B

Figure 4. Impeller-Funnel Overlap

Size

A

B

Size

A

B

122

12.75

0.130

245/245C

25.51

0.50

150

15.62

0.172

270/270C

28.11

0.55

165

17.18

0.203

300/300C

31.23

0.61

182/182C

19.00

0.38

330/330C

34.36

0.67

200/200C

20.82

0.41

365/365C

38.00

0.75

222/222C

23.16

0.45

MPLFN/MPLFS/MPLQN/MPLQS

Rotation

MPLFN, MPLFS,

MPLQN & MPLQS

Wheels

Figure 5. Proper Impeller Rotation

Verify that proper safety precautions have been followed.

Electrical power must be locked off.

WARNING