TXP Inst. & Maint. Manual: IM-825

45

3. Operate the fan at 50% of the maxi-

mum speed for at least 2 minutes.

4. Check the direction of rotation.

5. Set the desired work point.

6. For fans that cannot be used over

the entire characteristic curve, the

motor can be overloaded if the sys-

tem resistance is too low (due to

excessive current consumption). In

this case, throttle the volume flow

by reducing the operating fre-

quency.

7. Check the function of the protective

devices:

•

for IV / Omron: Clamp off the cold

conductor sensor start (observe all

safety instructions). The fan must

no longer start.

•

at IK Kostal: guaranteed with pre-

parameterization

8. Check the current consumption at

the operating point (if value is avail-

able). It must be less than the Full

Load Amps.

9. For customer-supplied frequency

inverters - check up and down

times.

10. Check the fan for unusual noises or

vibrations.

11. Measure the vibration levels.

12. Check the cooling air supply for the

electric motor.

13. Check the seal (only for sealed

fans).

Once everything is in order,

commissioning is complete and

the blower gate can be used.

5.7.4 Surge, Stall, Unstable

Operations

When the fan is operated to the left of

the maximum pressure of the character-

istic curve, pumping effects can occur in

the interaction between the fan and the

system. In a few cases, these pumping

effects can lead to an impairment of the

process result. In rare cases, unstable

operating conditions can occur, which

can lead to damage to the fan and the

connected system.

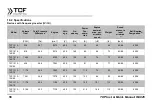

Fig. 31: Pump Effect

Unstable Operation

Performance Curve

q

V1

= Volume Flow at the Inlet

p

f

= Fan Pressure

p

fd

= Dynamic Fan Pressure

6

TROUBLESHOOTING

The following chapter describes possi-

ble malfunctions and their elimination. In

the case of frequent faults, the mainte-

nance intervals must be shortened and

adjusted according to the actual load. If

faults cannot be corrected by the follow-

ing notes, the manufacturer must be

contacted.