11

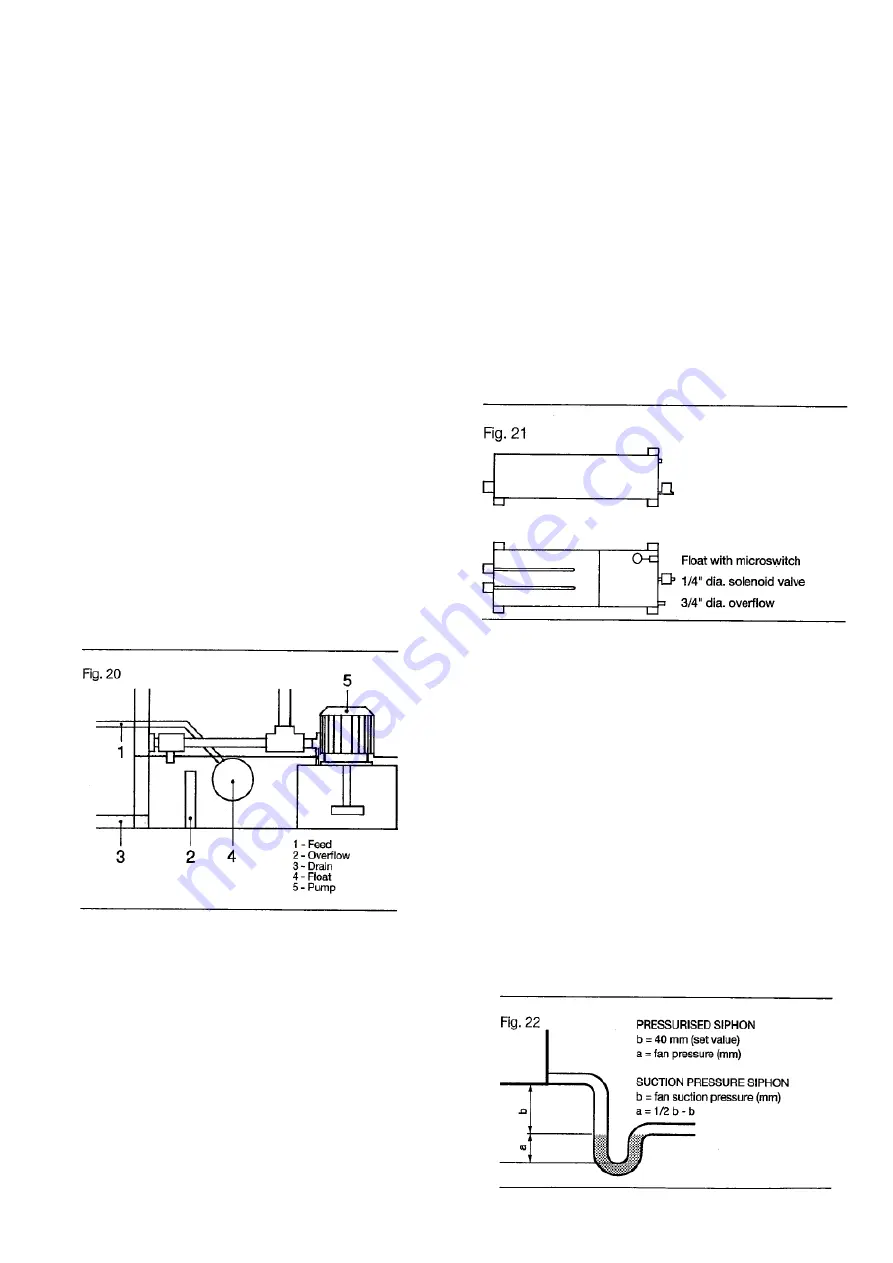

4.3.2. Hydraulic connections for cell block or spray

nozzle humidifiers

The hydraulic connections must be arranged so as to

permit easy extraction of the evaporating block or the

distribution ramp.

The drain and overflow must be fitted with a siphon a not

connected directly to the drainage system pipe (section

4.4.). This operation is extremely important in order to

prevent tank overflows and resulting flooding of the unit

and the site of installation.

We recommend you install the following devices on the

hydraulic connection to the mains:

- a filter

- a pressure gauge

- a flow control valve that also allows exclusion of the

humidification system.

4.3.3. Humidification with cell block

Prior to start-up, check that the cell block is correctly

installed (section 6.4.2.).

At first-time start-up, check that the cell block is evenly

wetted; if you observe water jets on its surface, restore

the regular water flow by means of the tap.

4.3.4. Humidification with circulating pump

To avoid damaging the pump at first-time start-up, check

that:

- The hydraulic connection has been made properly, in

accordance with prevailing regulations

- The tank is clean and free of any residue resulting from

installation that could cause its blockage

- The water level inside the tank is kept at 20-30 mm

below the overflow.

Should a situation arise in which there is no water in the

tank, the pump motor would overheat and be irreparably

damaged. Conversely, if there is too much water in the

tank, an overflow may result, leading to flooding of the

unit and the installation room.

4.3.5. Ultrasonic,

steam

(submerged

electrodes),

compressed air humidification

For Air Treatment Units with the above-listed types of

humidification, you should consult the MANUAL supplied

with the humidifier.

4.3.6. Steams humidifier with submerged elements

In order to make the system operational, you must:

- Connect up the element electrically in accordance with

prevailing standards

- Connect the humidifier to the mains network; an on-off

valve must be included to exclude the humidification

section from the line

- Connect the overflow to the drain to prevent flooding in

the case of float malfunction.

Before starting up the humidification system, you must:

- check the proper operation of the microswitch which, in

order to protect the element, interrupts the flow of

current when the water level drops below a permitted

level.

- check the setting of the float to prevent the overflow of

water from the tank.

4.4

DRAINAGE AND SIPHONING

Before positioning the Air Treatment Unit make sure you

have sufficient room to install the siphon and drainage

pipe.

The humidification and cooling exchanger sections of the

TCF Units are fitted with a threaded drain pipe projecting

laterally about 80 mm.

To allow the regular outflow of water every drain must be

fitted with a correctly sized SIPHON (fig. 22).