7. HYDRAULIC SYSTEM

- 122 -

They might occur when gears are runout or

insufficiently lubricated, or when oil pressure

is too high.

Contaminants in oil, too high oil temperature

(120

℃

[248

°

F] or higher), too frequently idle

operations

(a) Check for cracks or damage.

(b) Check wipe depth or wipe surface.

Oil pressure is too high.

Oil pressure is too high.

(a) Check shaft ends and keyways for cracks,

damage or undue wear.

(b) Check journal (in the area which slides on

the bearing) for discoloration, undue wear,

or roughness.

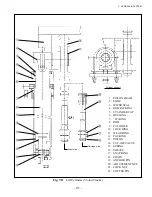

Name of component

①

Front cover

Items to be checked

(a) Check for cracks or damage.

Remarks (cause and others)

Oil pressure is too high.

(2) Inspection

CAUTION

1. Inspections are carried out to locate the cause of troubles and to determine whether parts

are reusable or not. Inspections must be carried out only by personnel with a certain

amount of knowledge and experience in hydraulic equipment.

2. The “useful limit” shown in this section should be used as a rough guide. We do not always

guarantee the performance of a part if it does not reach its useful limit.

CAUTION

The mating section between the front cover and the pump body looks black in some parts.

This is caused by the friction between aluminum parts and is not a problem.

②

Pump body (cast iron)

Useful limit

Wipe depth limit: less than 0.04 mm [0.0016 in]

(c) Check for signs of interference with gear at

discharge side.

③

Drive and driven gears

Runout of gears

Pump’s performance is not affected if there is

a sign of interference.

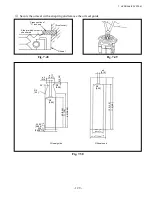

CAUTION

Useful limit

Roughness on journal (a):

0.8S - 1.6S

Roughness on oil seals (b and c):

1.6S - 3.2S

The shaft might have the following

scratches or scores on its outer diameter:

(a) Those caused by a hard object

between the shaft and bushing.

(b) Those caused by the oil seal’s main

lip

(c) Those caused by the oil seal’s dust lip

BUSHING

INPUT

SHAFT

OIL SEAL

BUSHING

SIDE PLATE

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

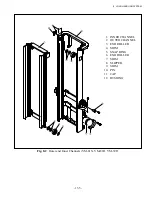

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...