7. HYDRAULIC SYSTEM

- 123 -

⑥

Gasket

(a) Check gaskets for proper installation or

cut.

(b) Check rubber parts for swelling.

(a) Check oil seal for round or peeled edge.

(b) Check main lip for warping outward.

(c) Check rubber parts for swelling.

Name of component

Items to be checked

(c) Check for discoloration, undue wear, or

roughness on the gears.

Remarks (cause and others)

Contaminants in oil, too high oil temperature

(120

℃

[248

°

F] or higher), too frequently idle

operations

The oil seal might be

damaged when the drive

gear is disassembled or

when it is removed from

the front cover. It is diffi

-

cult to locate the cause of

damage when removing

it from the front cover.

(d) Check gear teeth for roughness or

pitching.

(e) Check for missing or broken gear teeth

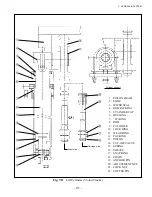

(a) Check side plate in the gear sliding area

for wear or nicks or scores.

(b) Check the gears for erosion at or near the

engagement area.

Irregular rotation at high speeds

Too high oil pressure or a hard object caught in

gear

Fine dust between side plate and gears

Cavitation or aeration

Useful limit

0.1 mm [0.0040 in] or less

④

Side plate

Useful limit

These areas

might be worn

Wear limit: 0.15 mm (0.006 in) or less

LBC surface

Discharge port

Erosion

might occur

here due to

cavitation.

Suction port

⑤

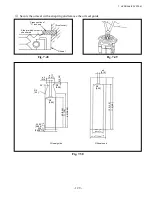

Bushing

The bushings are fitted

into front and rear

covers.

Check the inner surfaces of bushings for

roughness or wear.

The bushings are made of copper with the

back plate made of lead brass. The back plate

consists of porous and PTFE (polytetrafluoro-

ethylene) layers.

Useful limit

When the back plate of the bushing is exposed to view.

Too high oil temperature

Fire retardant hydraulic oil (phosphate) or

gasoline is used.

Wear occurs due to contaminants in oil, dust

which enters oil due to undue external negative

pressure, or rust due to moisture.

Increased internal oil leaks or high oil pressure

(0.2 - 0.3 MPa {2 - 3 kgf/cm

2

} [28.5 - 42.7 psi]

or more) applied on oil seal

Fire retardant hydraulic oil (phosphate) or

gasoline is used.

⑦

Oil seal

CAUTION

(continued from the

preceding page)

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...