8. LOAD HANDLING SYSTEM

- 146 -

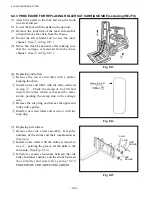

8.2.4 PROCEDURE FOR REPLACING ROLLERS AT MAST SIDE (excluding VM-77X)

(1) Remove the carriage from the inner channel

in the same procedure as described in “8.2.2

PROCEDURE FOR REPLACING ROLLERS

AT CARRIAGE SIDE.”

(2) Move the truck to a level surface and put the

both rear wheels on the bench of 250 – 300 mm

[9.8 – 11.8 in.] in height.

(3) Apply parking brake and block the both rear

wheels securely with blocks.

(4) Remove the bolt securing the lift cylinder and

inner channel, and hoist the inner channel with a

crane, keeping shims at the end of the piston rod.

(5) Remove the lift cylinder mounting both at the

lower section of the outer channel and cylinder

support at the middle section, and remove the

lift cylinder from the outer channel. Remove the

hydraulic hose with two wrenches, using caution

not to loosen the fittings at the cylinder side.

(6) Operate the crane to lower the inner channel

gradually and remove the end roller from the

lower section of the inner channel. At the

same time, the end at upper section of the outer

channel can also be removed.

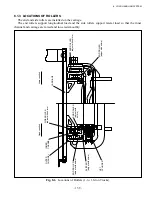

(7) Replacing end rollers

①

Remove upper end roller with a puller, keeping

shims.

②

Install a new end roller with the shims removed

in step

①

. Check for the stamp of S or SS

and install the roller which is marked the same

stamp, pointing the stamp side to the inner

channel side. (See Fig. 8.14.)

③

Replace the lower end roller, using same

procedure as above. In this step, point the stamp

side to the outer channel side.

(8) Operate the crane to hoist the inner channel. Place each roller into the channels.

(9) Install the lift cylinder and carriage in the reverse order of disassembly.

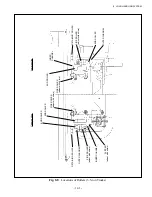

Fig. 8.18

Fig. 8.19

END ROLLER

SLIPPER

SHIM

SHIM

END

ROLLER

SHIM

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

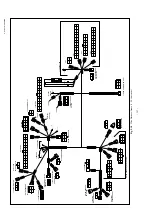

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

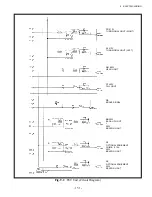

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

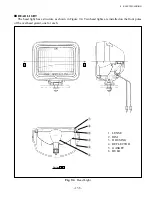

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...