2. MOTORS

- 27 -

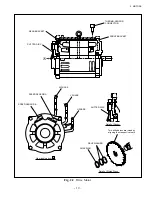

2.2.2 PUMP MOTOR

(1) Ball bearing

In case when the ball bearing gives out abnormal noise or seizes up, remove it from the armature

shaft.

For removing the ball bearing, apply a force to the outer race of the bearing by using a small-sized

puller. Do not use the bearing once removed.

For installing a new bearing, apply a force to the inner race of the bearing by using a cylinder-shaped

jig.

(2) Measurement of insulation resistance

Connect the negative (-) terminal of a meter to the motor yoke, and the positive (+) terminal to either

one of the two lead wires. Then measure the resistance. It is normal when the pointer of the meter

indicates higher than 1 M

Ω

.

If the meter reads than 1 M

Ω

, remove carbon deposit from inside the motor by blowing air, and dry it

by a dryer if available. Then measure the resistance again.

If the resistance measured again is lower than 1 M

Ω

replace the motor with a new one.

(3) Brush and brush spring checking

The brush has a marking on it to indicate wear limit. When the brush is worn to that limit, replace.

For measuring the tension of the brush spring that pushes the brush against the commutator, use a

spring balance.

Fig. 2.10

MARKING

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

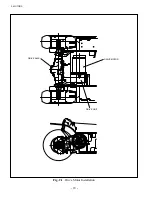

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

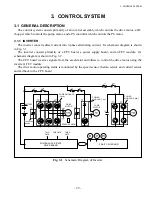

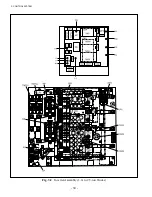

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...