- 37 -

3. CONTROL SYSTEM

3.2 MAINTENANCE

3.2.1 TROUBLESHOOTING GUIDE

The CPU board of the controller has an LED (green) which shows the content of errors occurring in

the truck, using their corresponding code numbers that are distinguished by different blinking intervals.

Each error code is displayed by a 2-digit decimal number, with both the second and first digits

blinking at an interval of 0.5 seconds while a pause of 1 second OFF is inserted between the second digit

and the first digit. Once an error code is displayed, an OFF period of 4 seconds is inserted before the

same error code is displayed again. Thereafter, this process is repeated.

If multiple errors occur, the code of the last error detected by the controller is only displayed.

Example: Error code: 23 (Traveling neutral interlock detected)

For errors whose error code is not displayed, refer to the following chart:

The same process

is repeated.

Error code number: 23

LED blinks twice

LED blinks three times

LED comes on

LED goes out

No.

1

2

3

4

Problem

Contactor won’t close

although key switch can

be turned on.

Truck won’t move

or operate (traveling,

load handling and EPS

systems)

CPU board LED of

controller won’t work.

Truck won’t travel

despite FR switch (F or

R) or accelerator pedal

operation.

Truck comes to stop

during traveling.

Hard steering wheel

Error

Harness disconnected

between power supply

board and CPU board

DSW1 improperly set

Reverse connection of

A and B connectors of

speed sensor.

U, V, or W phase wire

broken (missing)

Power module open

Accelerator pedal or

its signal circuit wire

broken

Battery overvoltage

detected

PS motor short-circuited

Remedy

Proceed with remedy in numerical order of encircled numbers.

Repair or change harness between CN1R (power

supply board) and CN9 (CPU board).

Set all DSW1 (2-bit SW) on CPU board to OFF.

Check A and B connectors for connection.

Check DU, DV, and DW cables for breakage, and

repair if needed.

Check power modules TMDU, TMDV, and TMDW

and repair if needed.

①

Check harnesses between CN2-8,9,20 (CPU

board) and traveling accelerator pedal, and repair

or change if needed.

②

Repair or change accelerator pedal unit.

①

Check battery connectors for contact.

②

Check harness between CN4-2 (CPU board) and

P3 terminal, and repair or change if needed.

③

Check harness between CN4-10 (CPU board)

and P13 terminal.

Check PS motor and wiring for short, and change if

needed.

Reset

Restore to

normal.

Restore to

normal.

Restore to

normal.

Restore to

normal.

Restore to

normal.

Restore to

normal.

Restore to

normal.

Remarks

Use caution when

replacing motor.

Protection is provided if

battery connectors cause

improper contact or get

disconnected during

regeneration.

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

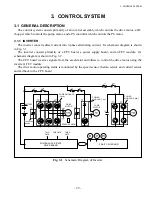

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...