- 45 -

3. CONTROL SYSTEM

■

Inspecting controller components

Do not touch any electrical component with the truck in conduction. When it is necessary to touch

an electrical component for any reason, such as inspection or maintenance, disconnect the battery

connectors and wait for more than 2 minutes before starting the operation.

If avoidable to inspect an energized truck, raise the drive wheels off the floor or ground to prevent the

truck from moving accidentally when the motor suddenly starts rotating for any reason.

In addition, use caution to prevent your body from touching the tires.

1. Checking electrical components of controller

(1) Tools and measuring equipment

(2) Tightening torque

No.

Name

Spec. & remarks

Use

Phillips and flat-bladed screwdrivers (large, medium,

Tighten and remove screws.

1 Screwdriver set

and small, one for each), flat-bladed screwdriver for

Set adjustment control.

small screws

2 Wrench set

7 mm, 13 mm, 17 mm

Tighten and remove bolts and nuts

(socket wrenches)

3 Torque wrench

Power module fitting screws: M4, M5

Measure tightening torque of power modules

4 Tweezers and pliers

Install and remove small parts

5 Ammeter

DC500A or 1000A

Measure electric current

6 Digital tester

up to 12 V, 30 V, 120 V

Measure voltage

Analog tester

range: x 1

Ω

, x 100

Ω

, x 1000

Ω

Measure resistance (digital tester cannot be used for this purpose.)

7 Oscilloscope

Check transistor circuit

8 Stabilized power

0 - 50 V, variable, 3A conductable

Check operation of each component.

supply for control

Where to tighten

Symbol

Truck

Model

Screw Torque

Remarks

Part name

Item

size

(N-m)

Printed circuit

Fixed

1 t

N61F30851=3

M4.5 1.0

board (CPU)

2 t

N61F30851=4

3 t, 3.5 t N61F30851=5

Printed circuit board

Fixed

Common N61F30841=7

M4.5 1.0

(power supply)

Power module

Fixed

TMDU

1 t

N51F45956=222

M5

2.5 ± 0.5 Heat-dissipation, insulation

TMDV/W

N51F45481=222

sheet is placed on the base.

TMP

N51F45956=216

For shape, see *1.

TMDU

2 t

N51F46529=224

TMDV/W

N51F46528=224

TMP

N51F45956=216

TMDU

3 t

N51F46529=124

TMDV/W

3.5 t

N51F46528=124

TMP

N51F45956=114

Power module

Fixed

Common N55F42549

M5

2.5 ± 0.5

Alminum block terminal Terminal

M8

9.8 ± 1

Capacitor board

Fixed & terminal CBD

1 t

N61F30830=221

M5

2.5 ± 0.5 M4 screw is used for two

CBP

N61F30831=215

M4

1.5 ± 0.2 studs of CBP.

CBD

2 t

N61F30813=230

CBP

N61F30831=215

CBD

3 t

N61F30813=150

CBP

3.5 t

N61F30831=114

Contactor

Fixed

MD

1 t, 3 t,

MA25M 46V

M5

2.5 ± 0.5

Terminal

MP

3.5 t

MA25M 46V

M8

9.8 ± 1

Fixed

MD

2 t

MA27M 46V

M5

2.5 ± 0.5

Terminal

MP

MA25M 46V

M8

9.8 ± 1

Contactor

Fixed

MPS

Common CM2-A DC48V

M4

1.5 ± 0.2

Terminal

M4

1.3 ± 0.2

Current sensor

Fixed

CSDU/W, CSP

Common S3CM7-800/4MD

M4

1.5 ± 0.2

IGBT

Fixed

TMPS1/2

Common 2MBI100N-60

M5

2.5 ± 0.5

Terminal

M5

2.5 ± 0.5

Capacitor CP5

Fixed

CPS

Common N71F41314

M4

1.5 ± 0.2 HFC-MPP63Y155K

+0.5

0

+0.5

0

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

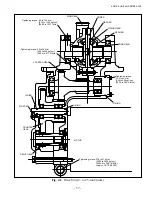

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

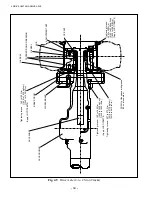

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...