5. BRAKE SYSTEM

- 76 -

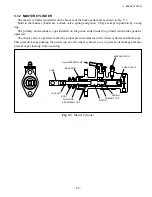

5.2.4 OPERATION TEST OF AUTOMATIC CLEARANCE ADJUSTER

(1) Set the outer diameter of the brake shoe to nearly the normal mounting dimension. Push up the

adjuster lever and adjust the diameter, turning the teeth of the adjuster.

When your finger is released, the teeth of the adjuster do not turn and the adjuster lever returns to

the original position.

Note:

If the teeth of the adjuster return with the lever, they are adjusted properly after mounting the

brake system on the truck.

(2) If the operation described above does not occur by pushing up the adjuster lever, take the following

measures:

(a) Check that the adjuster lever, adjuster, adjuster sprint, adjuster cable and shoe return spring are

securely installed.

(b) Check the shoe return spring and adjuster spring for deterioration, the adjuster for rotation, damaged

tooth or damage of the contact area with the teeth of the adjuster lever, and replace any defective

parts.

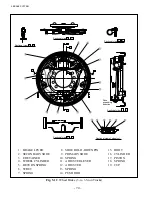

Fig. 5.28

Expanding part

Summary of Contents for FB10-7

Page 2: ......

Page 4: ...No SEB 81BBE...

Page 8: ...No SEB 81BBE...

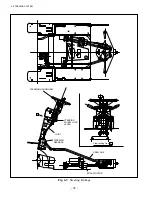

Page 9: ...No SEB 81BBE Fig 1 Overall Dimensions Unit mm in...

Page 10: ...No SEB 81BBE...

Page 28: ...1 BATTERY AND CHARGER 16 NOTE...

Page 30: ...2 MOTORS 18 DRIVE UNIT Fig 2 1 Drive Motor Installation DRIVE AXLE DRIVE MOTOR...

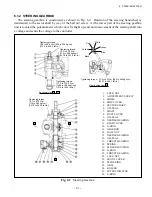

Page 42: ...3 CONTROL SYSTEM 30 Fig 3 2 Inverter Assembly 1 0 to 2 5 ton Trucks...

Page 43: ...31 3 CONTROL SYSTEM Fig 3 3 Inverter Assembly 3 0 to 3 5 ton Trucks...

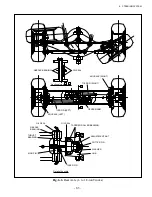

Page 44: ...3 CONTROL SYSTEM 32 Fig 3 4 Controller Wiring 1 0 to 2 5 ton Trucks...

Page 45: ...33 3 CONTROL SYSTEM Fig 3 5 Controller Wiring 3 0 to 3 5 ton Trucks...

Page 133: ...7 HYDRAULIC SYSTEM 121 Fig 7 27 Remove the oil seal from the front cover...

Page 160: ...8 LOAD HANDLING SYSTEM 148 NOTE...