English

TROUBLESHOOTING/TECHNICAL DATA

55

Technical specifications

Voltage:

230V ~ 50Hz

Output:

Motor 70 W

Lamp:

15 W, socket E14

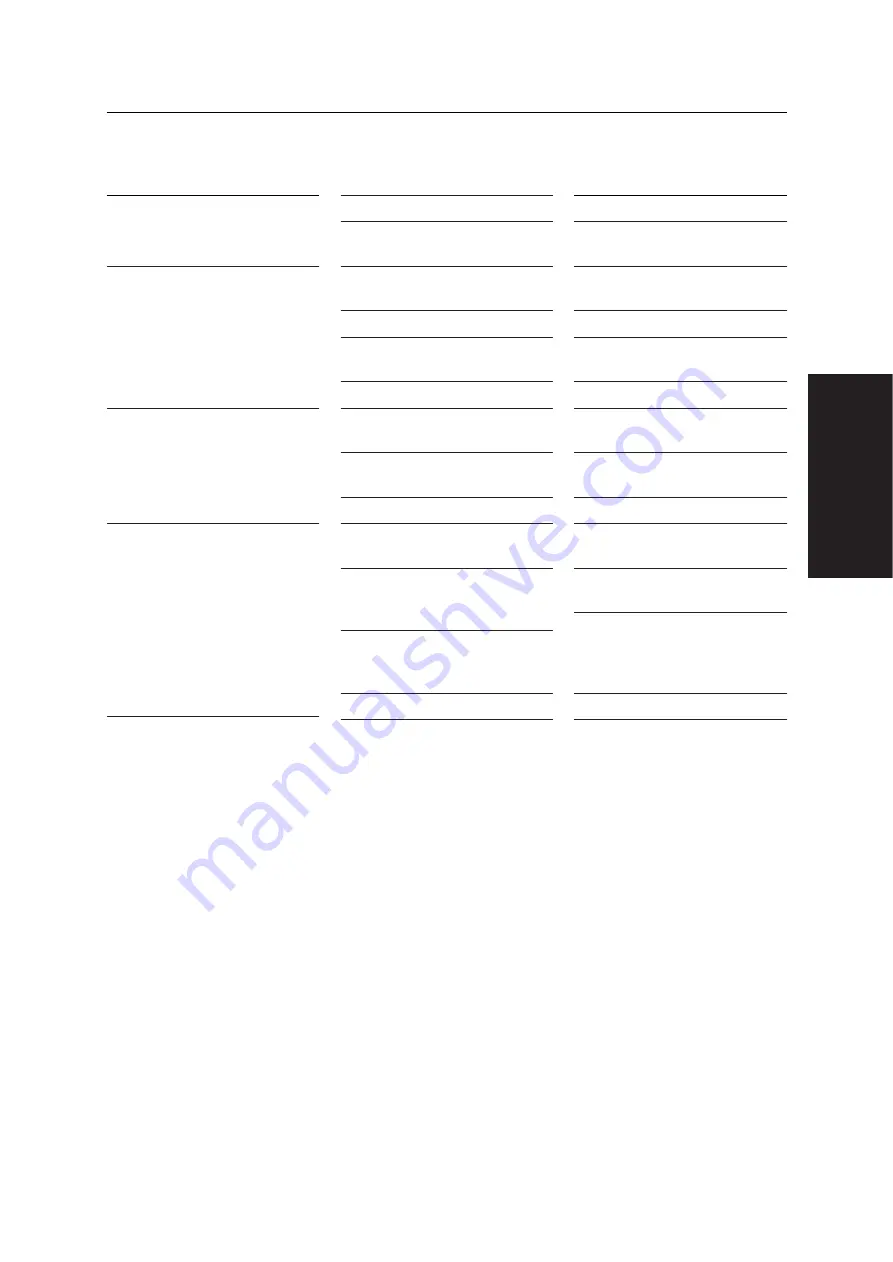

Solution

Reduce the tension.

Use a needle and thread

appropriate to the fabric.

Put the needle in again.

Replace the needle.

Match needle size to the

fabric and thread.

Change foot.

Thread needle correctly.

Match needle size to fabric

and thread and put needle in.

Increase thread tension.

Oil the sewing machine.

Clean shuttle and feed dog.

Clean sewing machine

thoroughly. Oil it exclusively

with sewing machine oil.

Replace needle.

Cause(s)

Threads pulled too tight.

Needle, thread and fabric do

not match each other.

The needle is inserted

wrongly.

The needle is damaged.

The needle is inserted

wrongly.

The wrong foot is attached.

The needle is improperly

threaded.

The needle, fabric and thread

do not go together.

Thread tension is too low.

The sewing machine needs

oiling.

Bits of fluff or old oil are stik-

king to the shuttle or the

needle shaft.

Cheap oil that has gummed up

the machine was used for

oiling.

The needle is damaged.

Fault

Fabric bunches up

Stitches are missed

Loose loops during sewing

Machine is noisy and

runs unevenly