TCNet Boiler Controller

User and Service Manual

23

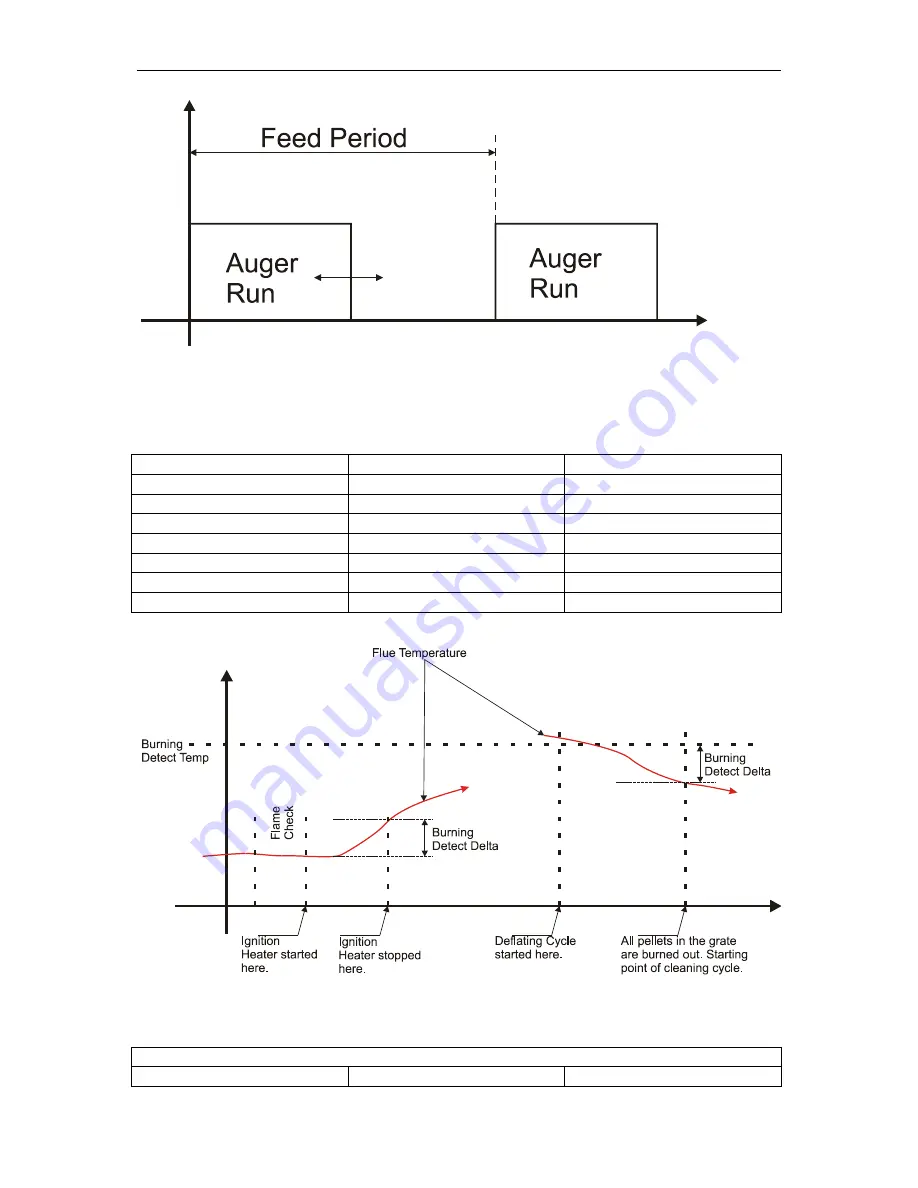

Graph 4 Feed Period

Ignition Data

Feed Time sec

60

Timeout min

10

Retries

3

Burn. Detect Temp :C

100

Burn. Detect Delta :C

7

[Graph5]

Auger Filling min

3

First run

0

Fan Speed

50

Graph 5 Burning Detection and Deflating Cycle

Circulation Data

Heating Circuit

Threshold

35