HR150, 200; ER150, 200 FRESH AIR VENTILATION SYSTEMS

11

68-0269

Airflow Balancing

Volume-balanced airflow in the ventilator is required. Volume

of outside air brought in must equal volume of air the unit

exhausts. If airflow is not correctly balanced:

• unit does not operate at its maximum efficiency.

• negative or positive air pressure can occur in the house.

• unit will not defrost properly.

• warranty can be voided.

Excessive positive pressure

can drive moist indoor air into

building external walls where it can condense (in cold

weather) and degrade structural components. Moist indoor air

can also cause keyholes to freeze.

Excessive negative pressure

can have several undesirable

side effects; in some geographic locations, soil gases such as

methane and radon can be drawn into the home through

basement/ground contact areas. Excessive negative pressure

can also cause back drafting of vented combustion equipment

when adequate combustion air supply is not provided.

Balancing Procedure

Six-inch (150 mm) diameter flow collars connected to inclined

or digital manometer, or magnehelic, with range of 0 to.25 in.

(0 to 62.5 Pa) of water are recommended for accurate airflow

measurements. To avoid airflow turbulence and incorrect

readings, flow stations should be located at a distant point of

at least five duct diameters; for example, 6 in. (150 mm) duct

requires five diameters x 6 in. (150 mm) = 30 in. (76 cm) from

nearest valve or flow restriction. This requirement applies to

both stale air to exchanger duct and fresh air to house duct.

Before balancing, make sure:

• all sealing of the ductwork system is completed.

• all of the ventilator system components are in place and

functioning properly.

• balancing dampers are fully open.

• unit is on High speed.

• airflows in branch lines to specific areas of house are

adjusted before balancing the unit. (A smoke pencil used at

the grilles is a good indicator of relative airflow for each

branch line.)

After taking readings in stale air and fresh air ducts, duct with

lower cfm (L/s) velocity reading should remain as is, while

duct with higher reading should be dampered back to match

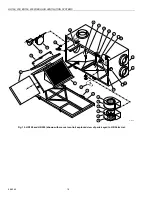

lower reading. See Fig. 12.

Return unit to appropriate fan speed for normal operation.

STARTUP AND CHECKOUT

After installation is complete, check to be sure system is

working correctly. On units with microprocessor control, select

ventilation speed by touching fan control pad on base module

until desired speed is indicated. On units with manual control,

turn speed selection knob to desired speed. Activate two-wire

control devices in system to make sure devices switch

ventilator to High speed. For operating instructions, see

instructions packed with digital fan timer. Leave instructions

with homeowner.

Fig. 11. Balancing airflow.

SERVICE

CAUTION

Electrical Shock Hazard.

Can cause personal injury or equipment damage.

Disconnect power to unit before starting maintenance.

For maximum efficiency, the Fresh Air Ventilation System

must be maintained on a regular basis. Total Comfort System

recommends checking and cleaning at least twice a year,

preferably at the beginning of each heating and cooling

season.

Cleaning Filters and Core

HR150 AND HR200 MODELS

Remove the room air filter, fresh air filter and heat transfer

core from the ventilator as a unit.

1.

Open ventilator door by loosening draw latches on top

of unit and swinging door open. For easier access,

remove door by moving it right to disengage hinges.

2.

Carefully grip ends of core, (be careful not to damage

aluminum fins); then pull evenly outward. Core fits

tightly, but slides out of channels.

3.

Once core is removed, filters can be removed by remov-

ing clips holding them in place. Note clip installation for

reassembly.

4.

Wash the filters and the core in warm soapy water. Do

not wash them in a dishwasher.

5.

Place the clean filter (wet or dry) over the core and

secure it in place with the clips.

6.

Reinstall core by sliding it into the four corner channels.

(Water cannot damage gasket and label on core ends,

so it is not necessary to remove them from the core.)

ER150 AND ER200 MODELS

1.

Open access door, carefully grip core ends and pull it

out evenly. Core fits tightly but slides out of cabinet.

2.

Remove filter clip, remove filters from core and rinse

filters with water or a combination of soap and water.

Do

not clean in a dishwasher.

3.

With filters removed, clean core with a vacuum cleaner.

Vacuum only filter sides of core to pull dirt back out of

core and not through it.

4.

Reinstall clean filter and reattach retaining clip.

5.

Reinstall clean core.

PUSH AND TURN WITH

SLOTTED SCREWDRIVER.

DAMPER AUTOMATICALLY

LOCKS WHEN PRESSURE

IS RELEASED.

M13462