HR150, 200; ER150, 200 FRESH AIR VENTILATION SYSTEMS

5

68-0269

Sizing

There are several methods that can provide satisfactory

results for sizing a ventilator to provide adequate ventilation

for a home. The ASHRAE Standard 62-1989 Ventilation for

Acceptable Indoor Air Quality suggests the following:

— .35 air changes per hour (ach) but not less than 15 cfm per

person for living areas = house size (sq ft) • ceiling height

(ft) / 60 (min) •.35 (ach)

Example:

= 2000 sq ft • 8 ft / 60 min •.35 ach = 93 cfm

— 50 cfm intermittent or 20 cfm continuous capacity for

bathrooms

Example:

50 cfm intermittent • 3 bathrooms = 150 cfm

20 cfm continuous • 3 bathrooms = 60 cfm

— 100 cfm intermittent or 25 cfm continuous capacity for

kitchens

Example:

100 cfm intermittent • 1 kitchen = 100 cfm

25 cfm continuous • 1 kitchen = 25 cfm

Option 1: Fresh Air Ventilation System provides continuous

fresh air supply of 93 cfm, and intermittent capacity for

bathrooms of 150 cfm. A separate 100 cfm exhaust fan is

used for the range hood.

Supply air flow required = 93 cfm

Exhaust air flow required = 150 cfm

Any Total Comfort System ventilation unit provides suitable

ventilation capacity. See Fig. 1.

Option 2: Fresh Air Ventilation System provides continuous

fresh air supply of 93 cfm, intermittent exhaust capacity for

bathrooms of 150 cfm, and continuous kitchen ventilation of

50 cfm.

Supply air flow required = 93 cfm

Exhaust air flow required = 200 cfm

Total Comfort System HR200/ER200 have the exhaust

capacity required to meet the ventilation needs of this

application. See Fig. 1.

Mounting Position and Location

The HR150/ER150 and HR200/ER200 can be suspended

from exposed ceiling joists or the ceiling surface, or floor

mounted. The ventilator must be level for the drains to

function properly.

• Locate the fresh air intake 6 ft (2m) or more from the stale

air exhaust to avoid re-entry of the exhaust air.

• Locate the ventilator where the length of ducting required is

minimal.

Install the HR150/ER150 and HR200/ER200 in a conditioned

space using these guidelines:

• Pipe the drain line from the ventilator to a drain.

• Use an existing electrical outlet with the appropriate

current rating (or install one) close to the ventilator power

cord.

• Allow space for the drain line by placing the ventilator at

least 10 in. (254 mm) off the floor.

• For access and removal of the ventilator core, allow at

least 25 in. (635 mm) of open space in front of the unit.

Ducting

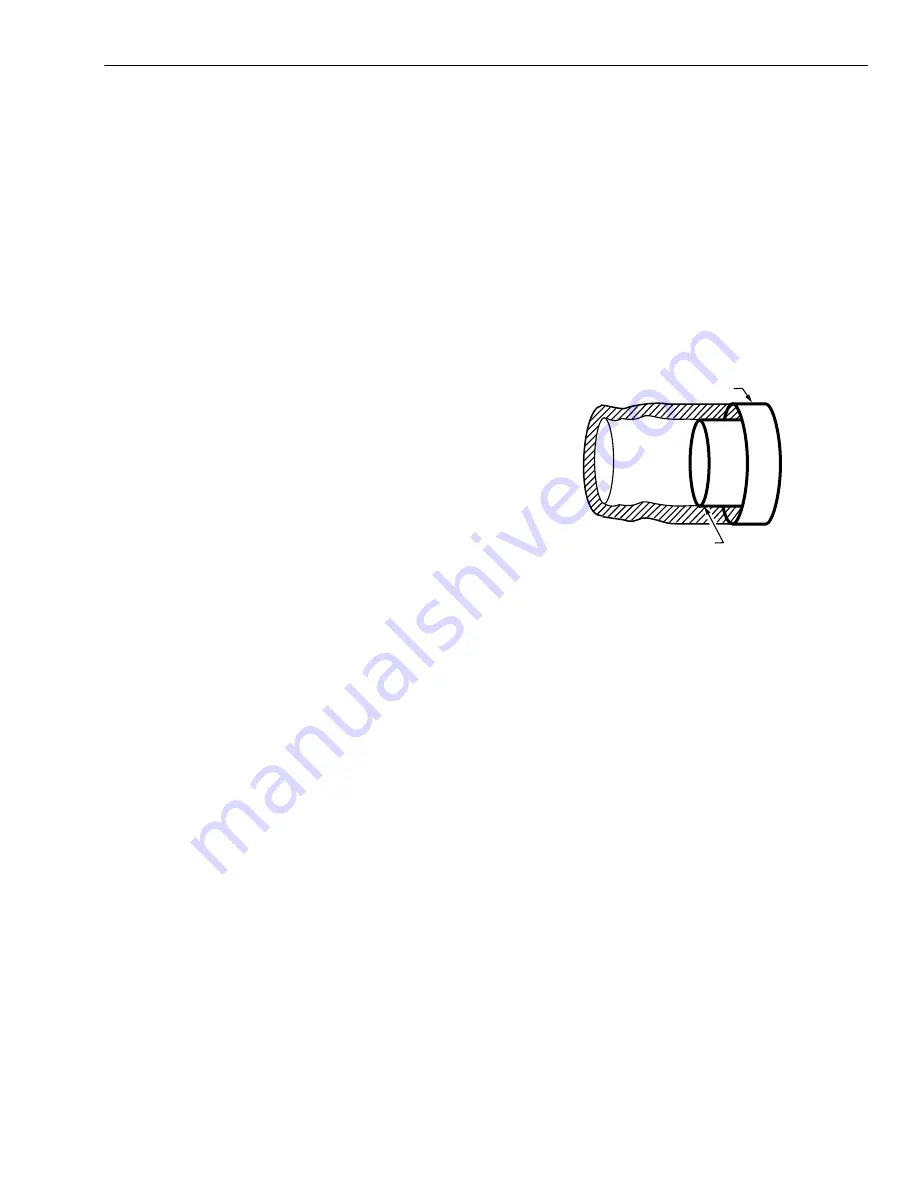

Ducting between the ventilator and the outdoors must be

insulated and have a continuous air vapor barrier. See Fig. 5.

IMPORTANT

All ducting to the outdoors must be terminated above

anticipated snow lines and be fitted with a weather

cap that incorporates bird screening.

Fig. 4. Sealing insulated duct terminations.

Design and installation of ductwork must be in accordance

with standard HVAC practice to deliver required quantities of

fresh air to the temperature-controlled space and exhaust

equivalent quantities of room air to the outside.

Keep intake and exhaust duct runs as short as possible with

few bends or elbows.

• Keep duct sizes as large as possible throughout the

installation.

• Use a 6 in. diameter round duct for all connections to and

from the ventilator.

• Separate outside intake and exhaust vents by at least 6 ft

(2m).

NOTES:

—

Do not locate the fresh air vent where it blows

directly onto occupants or the thermostat.

—

Do not locate the fresh air intake close to known

sources of pollutants such as automobile exhaust,

a dryer vent or chimney smoke.

• Ducting the supply outlet and/or the exhaust inlet of the

ventilator to the return air plenum of the air handler is an

excellent way to distribute fresh air and exhaust stale air

from all parts of the house, while reducing installation

costs. When choosing this method, balance the ventilator

when the air handler is running and interlock the ventilator

so that it can run only when the air handler runs. See

Fig. 6. An alternate method is to balance the ventilator

when the air handler is not running and let the ventilator

run whether the air handler is running or not, see Fig. 7. An

independent installation is shown in Fig. 8.

INSULATED

FLEX DUCT

COLLAR ON

VENTILATOR

SEAL INTERIOR LINING OF

FLEX DUCT TO INSIDE COLLAR

SEAL OUTER LINING OF FLEX

DUCT TO OUTER COLLAR

M6557