HR150, 200; ER150, 200 FRESH AIR VENTILATION SYSTEMS

9

68-0269

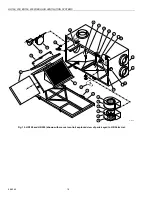

Fig. 8. Installing drain line.

Construct a P-trap using the plastic T-fitting provided.

1.

Cut two lengths of 1/2 in. ID hose and connect each

drain fitting to the end of the T-fitting.

2.

Position the center leg of the T-fitting so it points

upward.

3.

Connect the drain line to the center leg and tape it in

place to prevent any kinks. See Fig. 10.

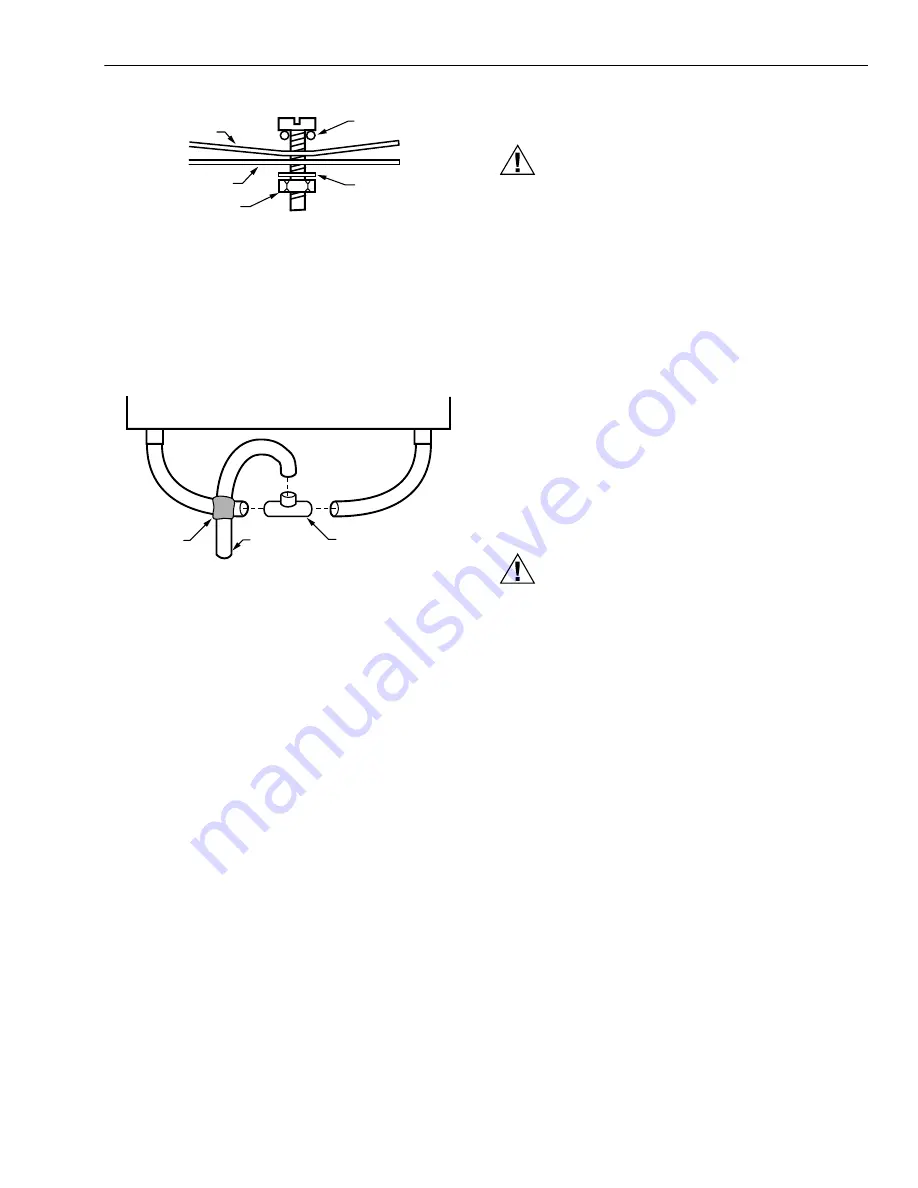

Fig. 9. Installing P-trap.

This creates a trap that will hold some condensation and

prevent odors from being drawn up through the drain hose

into the unit. If the unit is installed during a season when it is

unlikely that condensation will form, fill the trap with tap water.

WIRING

CAUTION

Electrical Shock Hazard.

Can cause personal injury.

Be sure the ventilator is properly grounded. To prevent

electric shock when cleaning or servicing the unit,

confirm the polarity of the power line that is switched

by the safety (disconnect) switch.

The hot line (black) is the proper line to be switched. See

Fig. 11. To confirm the proper polarity, use a voltmeter or test

lamp to make sure there is no power after the switch when the

door is open. Check between that point and ground (on the

cabinet). This process must be done because occasionally

some dwellings are improperly wired.

Heat Recovery Ventilator (HRV) and Energy

Recovery Ventilator (ERV) Connections

The connector is a 3-prong, 120 Vac plug with ground. If

further wiring is required, Honeywell recommends that a

licensed electrician make all electrical connections. It is very

important that the unit be properly grounded.

Digital Fan Timer Connections

CAUTION

Electrical Hazard.

Can cause equipment damage.

Disconnect HRV/ERV from power source before

connecting or disconnecting digital fan timer or other

device to HRV/ERV high-speed override terminals.

IMPORTANT

Do not connect external power sources to the high

speed override terminals.

Mount the digital fan timer in a full or one-half depth electrical

box in the living space. See Fig. 11 for the 20 minute timer and

the 20/40/60 minute timer wiring diagrams. (See accessory

parts list, items 9 through 11, for digital fan timer selection.)

M6552

DRAIN

PAN

O RING

HR

BOTTOM

WASHER

NUT

TO DRAIN

T FITTING

TAPE

M6551