TDI T

URBO

T

WIN

FROM

TECH DEVELOPMENT

Page 2

Publication T1-321

Issued November 15, 2013

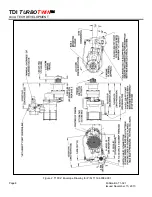

Figure 1

. Direction of Rotation viewed from Pinion End.

The maximum operating pressure identified on the

nameplate is measured at the check port on the starter

inlet with the starter in operation.

CAUTION

Exceeding the maximum pressure shown on the

nameplate may result in drive failure, damage to the

starter, or damage to the engine.

The housing proof pressure is 600 psig and is also

shown on the nameplate. This means that the turbine

housing will not burst when subjected to a static

pressure of 600 psig.

T

URBO

T

WIN

starters may not be used in areas that are

subject to explosion hazards under any circumstances.

1.3 PHYSICAL CHARACTERISTICS

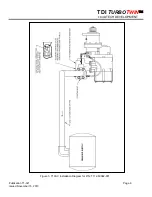

Figure 2 shows the configuration for the T100-V P/N:

T112-60082-001 with exhaust screen. This model

weighs approximately 54 lbs. and is 16.8 inches in

length. The turbine housing diameter is 6.8 inches,

which is common to all T100

T

URBO

T

WIN

air starters.

WARNING

Suitable hoisting gear must be used for the

transport and installation of the starter. If no hoisting

gear is available, the starter must be lifted from the

packaging by two people. Failure to comply with

this precaution may lead to back injuries. When

transporting the starter, wear suitable safety shoes.

CAUTION

When transporting the starter, wear suitable safety

gloves.

1.4 PERFORMANCE

The performance curve for the T100-V illustrates the

pinion torque versus pinion speed (rpm) at a constant

drive air pressure, and horsepower versus pinion

speed at a constant drive air pressure. The pinion

speed is shown on the horizontal axis while the pinion

torque is shown on the left edge of the vertical axis. Air

consumption rates are given for the various drive

pressures. The drive gas used for the performance

curve is air.

2.0 ORIENTATION OF THE STARTER

If the factory orientation of the starter turbine housing

assembly does not fit your engine installation, this

component can be re-oriented.

Determine the required orientation of the turbine housing

assembly and gearbox housing assembly. The turbine

housing assembly can be rotated to six different

positions relative to the gearbox housing assembly. The

drive assembly can be rotated to twenty four positions

relative to the inlet port.

Orientation of the starter should be accomplished prior to

installing the starter on the engine.

CAUTION

All screw threads are treated at the factory with a

fastener retention compound. Every screw and

tapped hole must be clean with a drop of Loctite 242

applied to the threads before being installed.

3.0 INSTALLING THE STARTER

Confirm the part number T112-60082-001 of the starter

on the nameplate is the one recommended by TDI.

A turbine air starter does not require lubrication in the

supply air. If a vane type starter motor is being replaced,

TDI recommends that all lubrication devices and lines be

removed to minimize flow restrictions.

WARNING

If a fuel (pulse) lubricator has previously been

installed in the system, disconnect and plug the line

to eliminate spraying diesel fuel on the engine.