TDI T

URBO

T

WIN

FROM

TECH DEVELOPMENT

Publication

T1-321

Page

7

Issued November 15, 2013

7.0 OPERATOR’S TROUBLESHOOTING GUIDE

TROUBLE PROBABLE

CAUSE

SOLUTION

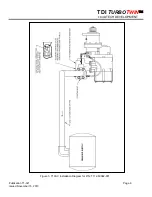

1. Air always flows through

exhaust

A. Relay valve improperly

installed.

A. Check typical installation

diagram and correct.

B. Relay valve not sealing

properly.

B. Check for damaged sealing

ring, replace relay valve or

damaged parts.

C. Solenoid is not sealing,

pressure remains in APP port of

relay valve.

C. Check solenoid potential at the

lead to ground should be 0. If not,

fix ignition switch problem.

2. Starter engages but does not

run,

A. Bad relay valve

A. Replace relay valve.

3. Starter does not run, small air

flow from turbine exhaust or

drive housing.

A. Nozzle blockage.

A. Remove blockage or obstruction

from nozzles.

4. Starter does not run. Normal

air flow from exhaust.

A. Excessive bends in the

supply line.

A. Shorten length or straighten

supply air line.

5. Pinion does not engage

A. Air pressure is too low

A. Increase air pressure to 40 -

150 psig.

B. Control lines to starter ports

reversed.

B. Check installation diagram and

correct.

C. Solenoid valve not operating

or plugged.

C. Check wiring and solenoid

operation. Correct wiring, remove

blockage, or replace solenoid

valve as needed.

D. Damaged pinion teeth.

D. Replace pinion or starter drive

as necessary.

6. Starter runs but engine cranks

slowly or not at all.

A. Air pressure too low

A. Increase air pressure to 40 –

150 psig.

B. Excessive back pressure.

B. Check Exhaust

C. Nozzle blocked or damaged.

C. Remove blockage or replace

damaged parts.

7. Starter continues to operate

after start button is released.

A. Solenoid valve is not sealing

correctly.

A. See 1C above

B. Relay valve is not sealing

correctly.

B. See 1B above

8. Air tank pressure decays after

extended shut down.

A. Air connections are not tight.

A. Tighten loose fittings. Repair or

replace damaged fittings.

B. Damaged air lines: crushed,

frayed, and kinked.

B. Replace damaged lines.

C. Relay valve is not sealing

correctly.

C. See 1B above

D. Solenoid valve is stuck open.

D. A. See 1C above