TDI TURBO

TWIN

FROM

TECH DEVELOPMENT

Publication

T1-932

Page

5

Issued May 20, 2016

Sparks will result from the engagement / disengagement

of the pinion with the flywheel gear. Users of this product

are hereby warned of this possibility, and advised to take

appropriate precaution.

The end user is responsible for taking appropriate action

to prevent ignition source from becoming effective.

Rubbing and friction can cause sparks or elevated

temperatures that may be a source of ignition of an

explosive atmosphere.

Starter Installation and Application

The air starter shall not be operated when an explosive

atmosphere is present.

Never use the starter on any application where there is a

possibility that a may be present. These gases cause a

high probability of explosion.

A work permit should be

used that ensures that

explosive atmospheres are not present in the zone of

operation during starter operation.

Do not install, maintain, or remove starter from engine in

the presence of a potentially explosive atmosphere.

Due to the possibility of accumulation of static discharge,

care must be taken to ensure the motor is properly

grounded at all times to prevent ignition hazards from

electrostatic discharge.

Air pressure above the maximum rated pressure on

starter nameplate, located on the starter housing may

result in a source of ignition caused by premature failure

of bearings or other components due to excessive

speed, output torque, or force.

Starter Maintenance

Removal from the engine is mandatory prior to any

maintenance being performed on the starter.

Do not perform maintenance or repairs when hazardous

atmospheres are present.

Take proper precaution and use protective equipment

when servicing/cleaning the engine flywheel housing.

WARNING

These special conditions must be followed for the

starter to conform to the ATEX Directive and for the

ATEX Declaration of Incorporation to be valid.

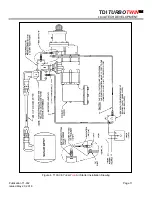

3.8 BEST INSTALLATION PRACTICES

Wear protective gloves and steel toe shoes when

installing air starter.

Follow engine manufacturer’s torque requirements

for all starter attachment screws.

For new installations or where new piping or

receiver tanks are installed,

always

purge the

starter supply line of debris before installing or

operating the air starter.

Install and maintain a 40-mesh (400 micron) Y-

strainer in the starter supply line to reduce the

level of contamination entering air starter.

To insure maximum performance and starter life,

use the recommended starter inlet and exhaust

piping sizes.

Limit the number of elbows installed in starting

system supply/exhaust lines and minimize to the

extent possible, the length of these lines to

prevent excessive flow losses and/or back

pressure.

Use a quick-opening starter relay valve to operate

air starter, and install within 10 feet of the air

starter inlet.

To properly control the starter, use a control valve

configured with 3 ports (IN, OUT, VENT). Use a

3-way valve only. Never use a 2-way or manual

ball valve to operate a pre-engaged starter

model or within the pre-engagement controls

piping.)

When a pressure regulator is required, locate this

at a minimum distance of 10 feet away from the

starter relay valve.

Utilize

pressure

regulator(s) with flow

characteristics that meet or exceed the selected

air starter’s flow requirements (Cu factor).

Regulators located far from the starter may

require sensing downstream pressure closer to

the starter inlet to deliver the desired dynamic

pressure to the starter while operating.

Do not use any mist or injection type

lubricators/devices in supply line to a TDI air

starter.

Where used in sub-freezing ambient

temperatures, install air starter with inlet and

exhaust in 6 o-clock position to allow drainage