TDI T

URBO

T

WIN

™

FROM

TECH DEVELOPMENT

Page

Publication T30-729, Rev. 2

Issued April 15, 2006

2

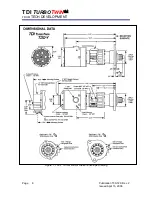

B. Note that the mounting flange assembly

can be rotated to twelve different positions

relative to the gearbox assembly (control

ports) and the gearbox housing assembly

can be rotated to four positions relative to

the inlet port. Additionally, the optional

exhaust housing can be rotated to eight

positions relative to the inlet port.

CAUTION

All screw threads are treated at the factory

with a fastener retention compound. Every

screw and tapped hole must be clean and

have a drop of Loctite 290 applied to the

threads before being reinstalled.

2.1.1 Pinion Housing Assembly Re-

Orientation

Remove the twelve mounting flange

attachment socket head cap screws.

Rotate the mounting flange to the desired

position and reinstall the twelve socket head

cap screws. Torque the twelve screws to

9.4 Lb-Ft. (12.7 Nm).

CAUTION

Ensure that the O-ring on the mounting

flange remains in position and is not cut.

2.1.2 Gearbox Assembly Re-Orientation

Remove the four tie bolts that secure the

gearbox assembly to the inlet assembly.

Rotate the gearbox housing / pinion housing

assembly to the desired position.

WARNING

Do not remove the five radial screws that

connect the inlet and turbine housing. The

inlet and turbine housing assembly must

remain in the same position, relative to each

other.

CAUTION

Ensure that the O-ring on the gearbox

assembly remains in position and is not cut.

Reinstall the four tie bolts. Torque the four

tie bolts to

9.4 Lb-Ft. (12.7 Nm).

CAUTION

Because of the length of the tie bolts, too

much torque may weaken or break them.

DO NOT OVER-TORQUE.

2.1.3 Inlet Assembly Orientation

Refer to Section 2.1.2.

After removing the four tie bolts, rotate the

inlet assembly to the desired position

relative to the control ports on the gearbox.

Align the components and reassemble per

Section 2.1.2.

CAUTION

Ensure that the O-ring on the gearbox

assembly remains in position and is not cut.

2.2 Model T30-U Flange Mount

Orientation

A. Determine the required orientation of the

flange assembly, gearbox assembly, and

any optional exhaust port.

B. Note that the mounting flange assembly

can be rotated to twelve different positions

relative to the gearbox assembly (control

ports) and the gearbox housing assembly

can be rotated to four positions relative to

the inlet port. Additionally, the optional

exhaust housing can be rotated to eight

positions relative to the inlet port.

CAUTION

All screw threads are treated at the factory

with a fastener retention compound. Every

screw and tapped hole must be clean and

have a drop of Loctite 290 applied to the

threads before being reinstalled.

2.2.1 Mounting Flange Re-Orientation

Remove the twelve mounting flange to

pinion housing assembly socket head cap

screws.