TDI T

URBO

T

WIN

™

FROM

TECH DEVELOPMENT

Publication T30-729, Rev. 2

Page

Issued April 15, 2006

3

Rotate the mounting flange to the desired

position and reinstall the twelve cap screws.

Torque the twelve screws to

9.4 Lb-Ft. (12.7

Nm).

CAUTION

Ensure that the O-ring on the pinion housing

remains in position and is not cut.

2.2.2 Gearbox Assembly Re-Orientation

Remove the four tie bolts that secure the

gearbox housing assembly to the inlet

assembly.

Rotate the gearbox housing and pinion

housings assembly to the desired position.

WARNING

Do not remove the five radial screws that

connect the inlet and turbine housing. The

inlet and turbine housing assembly must

remain in the same position, relative to each

other.

CAUTION

Ensure that the O-ring on the gearbox

housing assembly remain in position and is

not cut.

Reinstall the four tie bolts. Torque the four

tie bolts to

9.4 Lb-Ft. (12.7 Nm).

CAUTION

Because of the length of the tie bolts, too

much torque may weaken or break them.

DO NOT OVER-TORQUE.

2.2.3 Inlet Housing Assembly Re-

Orientation

Refer to Section 2.2.2.

After removing the four tie bolts, rotate the

inlet assembly to the desired position

relative to the gearbox control ports. Align

the components and reassemble per

Section 2.2.2.

CAUTION

Ensure that the O-ring on the gearbox

assembly remains in position and is not cut.

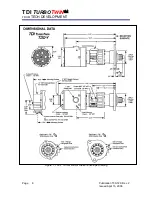

3.0 INSTALLING THE STARTER

A Typical T30 Series installation is shown in

Figure 2. The components illustrated may

vary in shape, but there must at least be a

start switch, air tank, and air piloted relay

valve to correctly operate a T30 Series

starter.

NOTE

Mounting the air piloted relay valve on the

starter is preferred in installations where

space is available.

TDI recommends mounting the air piloted

relay valve no more than 3 meters (10 feet)

from the starter’s inlet port, and as close to

the starter as possible. If the starter is being

installed on a vehicle where the air tank is

within 3 meters (10 feet) of the starter, then

the relay valve may be mounted on the tank.

In installations where the tank is more than 3

meters (10 feet) from the starter, then the

relay valve must be mounted within 3 meters

(10 feet) of the starter.

A turbine driven starter does not require

lubrication in the supply air. Therefore, if a

vane-type starter motor is being replaced,

TDI recommends that all lubrication devices

and lines be removed to minimize flow

restrictions.

WARNING

If a fuel (pulse) lubricator has previously

been installed in the system, disconnect and

plug the line to eliminate spraying diesel fuel

on the engine.

Liberally grease the starter’s pinion teeth

with chassis lube and then mount the T30

Series starter on the engine. Tighten all

mounting hardware as appropriate.

After mounting the starter to the engine,

attach the supply air line from the tank, the

control air lines, and the solenoid to the

ignition system and air piloted relay valve.

TDI recommends installation of a “Glad

Hand” / quick disconnect for auxiliary

pressurization of the air tank.