TDI T

URBO

T

WIN

™

FROM

TECH DEVELOPMENT

Page

Publication T30-729, Rev. 2

Issued April 15, 2006

4

Because turbine starters such as the T30

Series are sensitive to flow restrictions, care

must be taken to use uniform hose or tubing

and fittings for connection of the supply air

line. Tees, elbows, and line length must be

kept to a minimum. TDI recommends that

hose or flex couplings be installed to

eliminate possible leakage caused by strain

on the supply air line.

Normally an air strainer is not required. In

dirty environments, use of a #40 mesh Y-

strainer is recommended.

Only type approved metallic hose

assemblies are approved in permanently

pressurized compressed air lines of starters.

Non-metallic hose assemblies are allowed

only in case the piping system will be

emptied after the starting procedure.

Pipe unions must be type approved by GL.

Downstream of the pressure regulator a

pressure relief valve is to be provided.

WARNING

Recheck all connections for tight fit.

Fill the air system tank. The T30 Series

starter is now ready to operate.

4.0 STARTER OPERATION

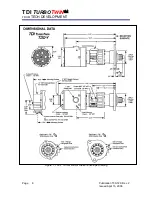

The maximum operating pressure limit is the

inlet pressure when measured at the starter

inlet pressure check port during the crank

cycle. In order to check the starter inlet

pressure, a 1/8" NPT pipe tap connection is

provided in the inlet housing to attach a

pressure gauge. Refer to figure 1. IN NO

CASE SHOULD INLET OPERATING

PRESSURE EXCEED 10.3 BAR (150

PSIG).

WARNING

Do not operate the TDI Turbotwin T30

Series air starter with air pressure greater

than the pressure rating on the nameplate.

This pressure is to be measured at the

starter inlet while the starter is running.

The static supply pressure will always be

higher than the operating pressure. As a

guideline, the maximum pressure limit (proof

pressure) that the T30 Series starter may be

subjected to is 20.7 Bar (300 PSIG).

System pressure that exceeds the maximum

operating limit must use a pressure reducer

device to ensure that the operating pressure

limit to the T30 Series starter is maintained.

System pressure that exceeds the 20.7 Bar

(300 PSIG) limit must, in addition to a

pressure reducer device, incorporate a

pressure relief valve set below 20.7 Bar (300

PSIG) in the supply air line.

All appropriate local pressure codes and

pressure limitations on other system

components must be adhered to and would

supersede the guidelines given in this

manual.

Follow the engine manufacturer’s

instructions for starting the engine.

WARNING

Do not engage the starter while the engine

is running.

If the starter fails to function properly when

first operated, or its performance

deteriorates with use, refer to the Operator’s

Trouble Shooting Guide, Section 6.0. If you

cannot solve the problem, or repair is

necessary, contact your local TDI

Turbotwin™ distributor or dealer.

TDI turbine starters share a common

characteristic known as “coast-down”. Once

unloaded, turbines must coast to a stop from

their unloaded or

free-speed

. Turbines

behave differently in this respect, when

compared to positive displacement devices,

because the friction (drag) of rubbing,

sealing surfaces (piston rings or vanes)

quickly stops an unloaded machine. Less

encumbered by drag, and typically

decelerating from much higher operating

speeds, turbines can take considerably

longer to come to rest.