PAH300

・

350S24

-SERIES

TDK-Lambda

10

+

+

+

-

Load

Load

+

-

+V

+S

-S

-V

TRM

+V

+S

-S

-V

TRM

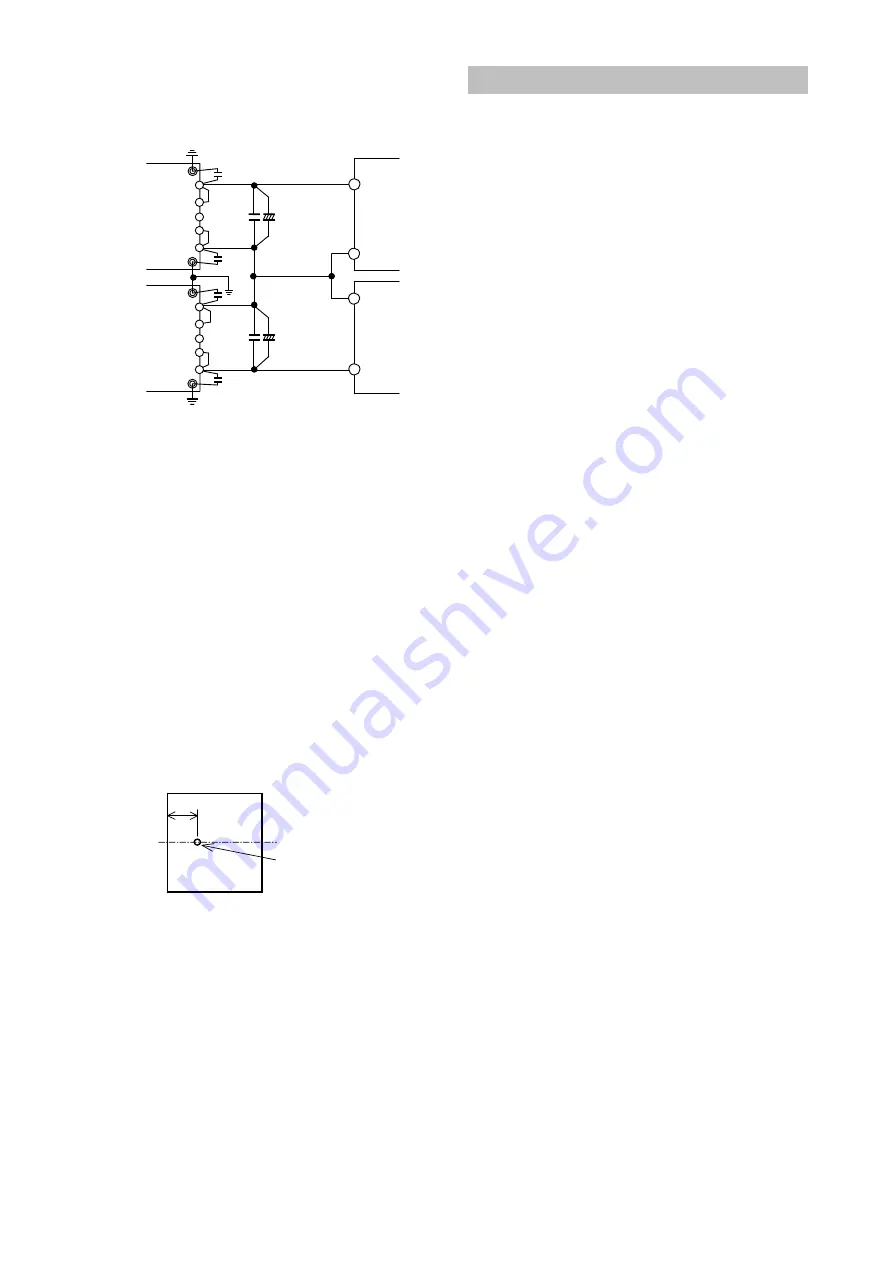

Fig.12-2 Series Operation due to

±

Output

13. Operating ambient Temperature

There is no restriction on mounting direction but there

should be enough consideration for airflow so that heat

does not accumulate around the power module vicinity.

Determine external components configuration and

mounting direction on PCB such that air could flow

through the heatsink at forced cooling and conventional

cooling.

By maintaining actual baseplate temperature below

100

℃

, operation is possible.

For details on thermal design, refer to Application

Notes “Thermal Design”.

Note :

Maximum baseplate temperature is 100

℃

. For worst

case operating condition, verify baseplate temperature at

measurement point indicated in fig. 13-1.

Measurement Point

of Baseplate

Temperature

21mm

Input Side

Output Side

CL

Fig.13-1 Measurement Point of

Baseplate Temperature

For better improvement of power module reliability,

derating of baseplate temperature when using is

recommended.

14. Operating Ambient Humidity

Take note that moisture could lead to power module

abnormal operation or damage.

15. Storage Ambient Temperature

Abrupt temperature change would cause moisture

formation that leads to poor solderabilty of each

terminal of the power module.

16. Storage Ambient Humidity

Take enough care when storing the power module

because rust which causes poor solderability would form

in each terminal when stored in high temperature, high

humidity environment.

17. Cooling Method

Operating temperature range is specified by the

baseplate temperature. Therefore, several methods of

heat dissipation are possible.

For details on thermal design, refer to Application Notes

“Thermal Design”.

18. Baseplate Temperature vs. Output

Voltage Drift

Output voltage drift is defined as the rate of voltage

change when baseplate temperature only is changed during

operation.

19. Withstand Voltage

This power module is designed to have a withstand

voltage of 1.5kVDC between input and baseplate,

1.5kVDC between input and output and 500VDC

between output and baseplate for 1 minute. When

conducting withstand voltage test during incoming

inspection, be sure to apply DC voltage. Also, set the

current limit value of the withstand voltage testing

equipment to 10mA.

Be sure to avoid conducting test with AC voltage

because this would cause power module damage.

Furthermore, avoid throw in or shut off of the testing

equipment when applying or when shutting down the

test voltage. Instead, gradually increase or decrease the

applied voltage. Take note especially not to use the

timer of the test equipment because when the timer

switches the applied voltage off, impulse voltage which

has several times the magnitude of the applied voltage

is generated causing damage to the power module.

Connect the terminals as shown in the diagram below.