CME-5

CME

・

All specifications are subject to change without notice.

• These products are Class

Ι

and must therefore be reliably

earthed and professionally installed in accordance with the

prevailing electrical wiring regulations and the safety standards

covered herein.

• These products are IPX0, and therefore chemicals/solvents,

cleaning agents and other liquids must not be used.

• The first protective earth connection in the final installation must

be marked with the protective earth symbol.

General installation instructions

• These products are designed for continuous operation within an

overall enclosure, and must be mounted such that access to the

mains terminals is restricted. See Clause 16, IEC/EN/UL60601-1.

• These products are NOT suitable for use in the presence of

flammable anaesthetic mixtures with air or with oxygen or with

nitrous oxide.

• These products are classed as ordinary equipment according to IEC/

EN/UL60601-1 and are NOT protected against the ingress of water.

• Connect only apparatus complying with IEC/EN/UL60601-1 to

the signal ports.

• Except for permanently installed equipment as defined in Clause

57.6 of IEC/EN/UL60601-1 the overall equipment in which these

products are installed must have double pole fusing on the input

mains supply. The products themselves have single pole fusing

in the live line.

• These products provide reinforced insulation between mains

and output, with reference to IEC/EN/UL60601-1.

• Reference should be made to local regulations concerning the

disposal of these products at the of their useful life.

• These products have not been assessed to IEC/EN60601-1-2

(EMC) but EMC test data is available from TDK-LAMBDA

Corporation.

Special Instructions for IEC/EN/UL/ 60601-1

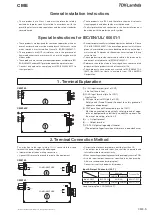

1. Terminal Explanation

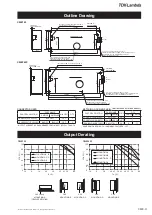

CME150

CME240P

(1) L: AC input terminal (pin 1 of CN1)

Live line (fuse in line)

(2) N: AC input terminal (pin 3 of CN1)

Neutral line

(3) FG: Input terminal FG (pin 5 of CN1)

Safety earth (Frame Ground) Connect to safety ground of

apparatus or equipment.

(4) FG: Frame Ground (Connected to pin 5 of CN1)

Must be connected to electrically safety ground of appa-

ratus or equipment by electrically conductive spacers. For

the way of mounting, refer to 4-2

(5) + : + Output terminal

(6)

-

:

-

Output terminal

(7) V.ADJ: Output voltage adjust trimmer.

(The output voltage rises when a trimmer is turnedclockwise.)

2. Terminal Connection Method

Pay attention to the input wiring. If it is connected to wrong

terminal, the power supply will be damaged.

• Input must be off when making connection.

• Connect FG terminal to ground terminal of the equipment.

CME150

CME240

• Output current of each terminal pin must be less than 5A.

• The output load line and input line shall be separated and

twisted to improve noise sensitivity.

• When connecting or removing connector, do not apply stress to PCB.

• Use the input/output connector specified in outline drawing.

Also, use recommended crimping tool.

Connector is not included with this product.

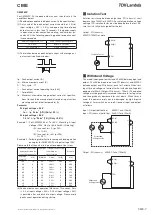

Input & Output Connector (J.S.T)

Connector

Housing

Terminal Pin

CME150

CME240P

Input: CN1

B3P5-VH

VHR-5N

SVH-1T-P1.1

Output: CN51

B6P-VH

VHR-6N

VHR-8N

SVH-1T-P1.1

Hand Crimping Tool : YC-160R(J.S.T)

5

3

1

FG

N

L

CN1

VR51

CN51

1

-

+

2

3

4

5

6

OUTPUT

INTPUT

COMPONENT SIDE

COMPONENT SIDE

-

+

OUTPUT

LOA

D

(%

)

LOA

D

(%

)

85VAC

265VAC1

5

3

1

FG

N

L

CN1

INTPUT

85VAC

265VAC1

CN51

VR51

1

2

3

4

5

6

7

8

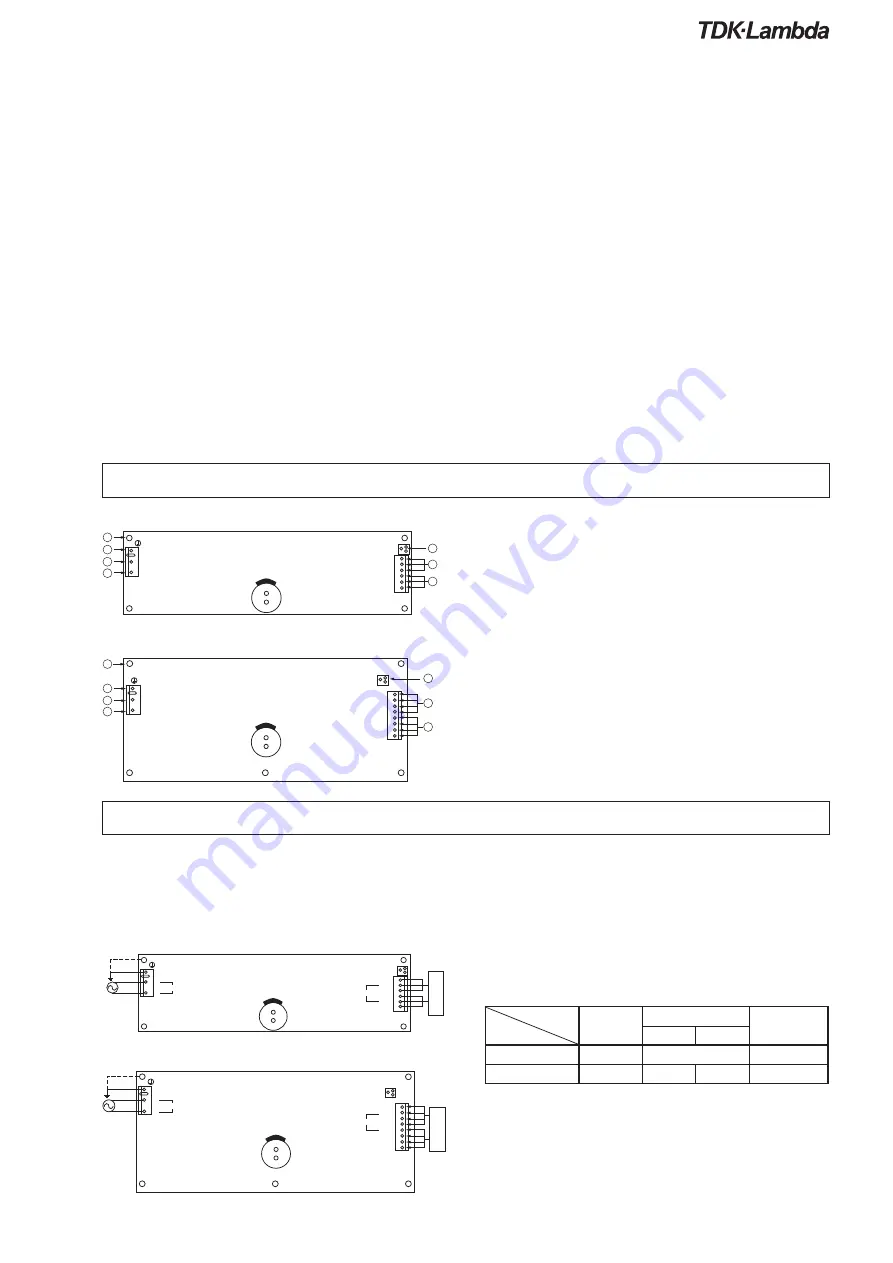

5

3

1

FG

N

L

CN1

VR51

CN51

1

2

3

4

5

6

1

2

3

4

5

6

7

CN51

VR51

1

2

3

4

5

6

7

8

5

3

1

FG

N

L

CN1

1

2

3

4

5

6

7