3

TDK-Lambda

PFE300SA

・

500SA Series

INSTRUCTION MANUAL

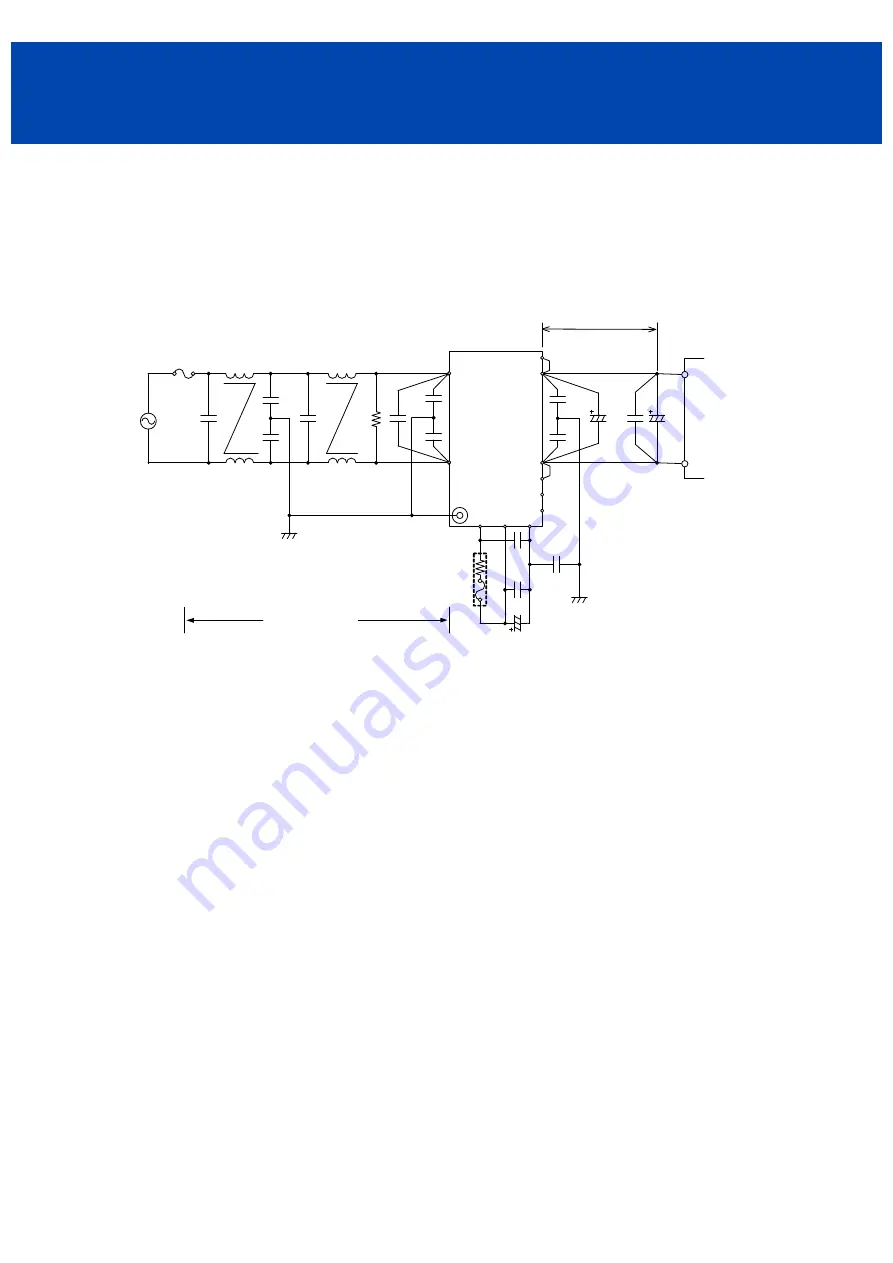

5. Terminal connecting method

In order to use the PFE300SA,500SA Series, this module must be connected with external components

according to Fig.5-1.

Pay attention to the each wiring. If it is connected to wrong terminal, the power supply will be damaged.

PFE300SA,500SA Series employs conduction cooling method. Use heat sink and fan to dissipate heat.

For selection of heat sink and heat sink dissipation method, refer to the Power Module Application Note.

Fig.5-1 Basic connection

C7

C6

C4

C5

C3

C2

C10

C8

F1

PFE300SA

PFE500SA

AC(L)

AC(N)

+V

-V

+S

-S

TRIM

ENA

-BC

+BC

R

C1

L1

L2

R1

BASE -PLATE

TFR1

C11

C12

L= 50mm

C13

C9

C14

C15

C16

Load

+

-

Input Filter

(For VCCI-classA )