28

83550001 Revision C

7.2.

Isolated Analog Programming (INA option)

The INA option features galvanically isolated analog voltage/current programming/readback,

and digital control/readback connections. Signals are isolated using fiber optics. The

Accuracy, Linearity, Temperature coefficient and Stability specifications are limited to

±0.01% when programming via the isolated analog interface. If the unit is equipped with

floating return, the isolated analog interface should be specified.

The interface pin connections are similar to the ANA interface except the front panel

potentiometer wipers (pins 4 and 5) are not connected. Details are shown in Table 6 below.

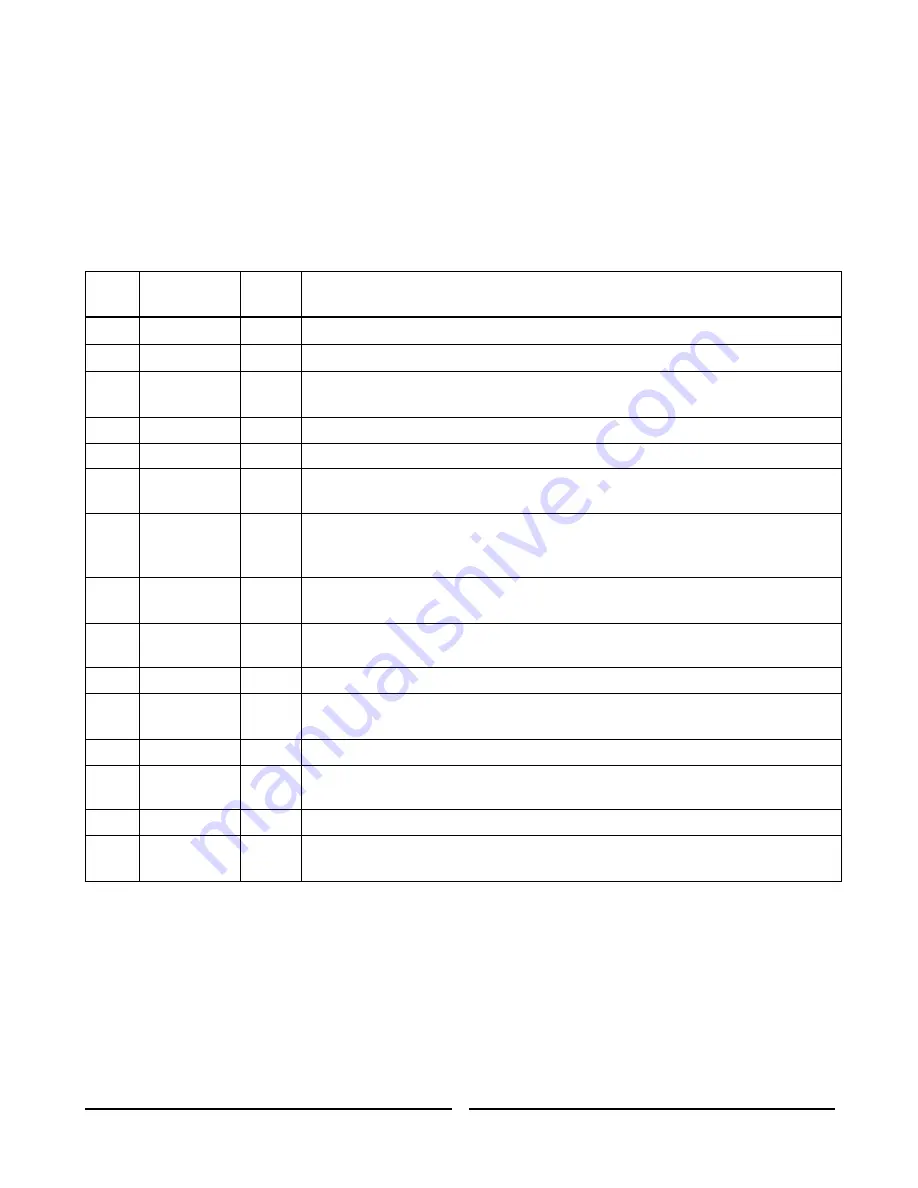

Pin

Signal

Name

I/O

Description

1

CC LED

O

+15V through 10k

when unit is operating in Constant Current mode

2

CV LED

O

+15V through 10k

when unit is operating in Constant Voltage mode

3

I-MON

O

Analog output current monitor signal, scaled 0-10V=0-100% rated

current. Series resistance is 11k

4

N/C

Not connected

5

N/C

Not connected

6

Digital

Ground

Ground for digital circuits, Isolated from chassis to 2,000V

7

POL-SET

I

Polarity set signal for units equipped with optional electronic polarity

reversal. Open=positive polarity, connected to digital ground=negative

polarity.

8

V-SET

I

Output voltage set point, scaled 0-10V=0-100% rated voltage.

Resistance to ground approx. 10M

9

Analog

Ground

Analog ground, Isolated from chassis to 2,000V

10

+10V

O

+10V reference, 2mA max.

11

V-MON

O

Analog output voltage monitor signal, scaled 0-10V=0-100% rated

voltage. Series resistance is 11k

12

HV ON

I

Open=HV OFF, Connect to digital ground=HV ON

13

POL-

Status

O

Output Polarity indicator for units equipped with optional electronic

polarity reversal. +12V=Positive, 0V=Negative.

14

N/C

Not connected

15

I-SET

I

Output current set point, scaled 0-10V=0-100% rated current.

Resistance to ground approx. 10M

Table 6. Isolated Analog Interface Signals (INA option)

Remote operation via the INA interface is the same as the ANA interface. Note that the

control modes described in sections 7.1.2 through 7.1.4 cannot be used.

Summary of Contents for PHV Series

Page 11: ...8 83550001 Revision C 2 SPECIFICATION...

Page 12: ...9 83550001 Revision C Mechanical Details...

Page 14: ...11 83550001 Revision C This Page Left Intentionally Blank...

Page 26: ...23 83550001 Revision C This Page Left Intentionally Blank...

Page 32: ...29 83550001 Revision C This Page Left Intentionally Blank...

Page 34: ...31 83550001 Revision C This Page Left Intentionally Blank...

Page 36: ...33 83550001 Revision C This Page Left Intentionally Blank...

Page 37: ...34 83550001 Revision C Notes...