8

V

ersa

s

afe

TM

I

nsTallaTIon

CONCRETE STRENGTH

The floor at the installation location should

consist of commercial-grade concrete

measuring at least

2000 psi

in compres-

sion strength.

The full effectiveness of

the mounting anchors depends upon

meeting this specification!

Check with

the contractor/builder or owner of the

installation to verify that this requirement

can be satisfied.

SELECTING THE

INSTALLATION LOCATION

Choosing the right location for your

unit is very important. Security con-

cerns suggest a location that is away

from any door or external access point.

Ideally, the terminal should be mounted

as close to a back wall as possible.

Wherever you decide to locate the

terminal, be sure to follow the recom-

mended procedures for both mounting

the unit.

Mark the location of the cabinet mounting holes on the concrete floor. This is

accomplished as described below,

(see figure 1)

.

1.

Move the unit to the location where it will be installed. Open the cabinet vault

door at least 90° to improve access. Locate the four (4) anchor-bolt holes in

the bottom of the cabinet (each corner). Use a felt-tip pen or other marker to

carefully mark the center of each of the four corner holes on the floor; these

marks will serve as guides for the anchor bolt holes that will be drilled in the

next step. Move the unit aside to provide clear access to the mounting hole

marks. Center punch each mark to help align the drill bit.

2.

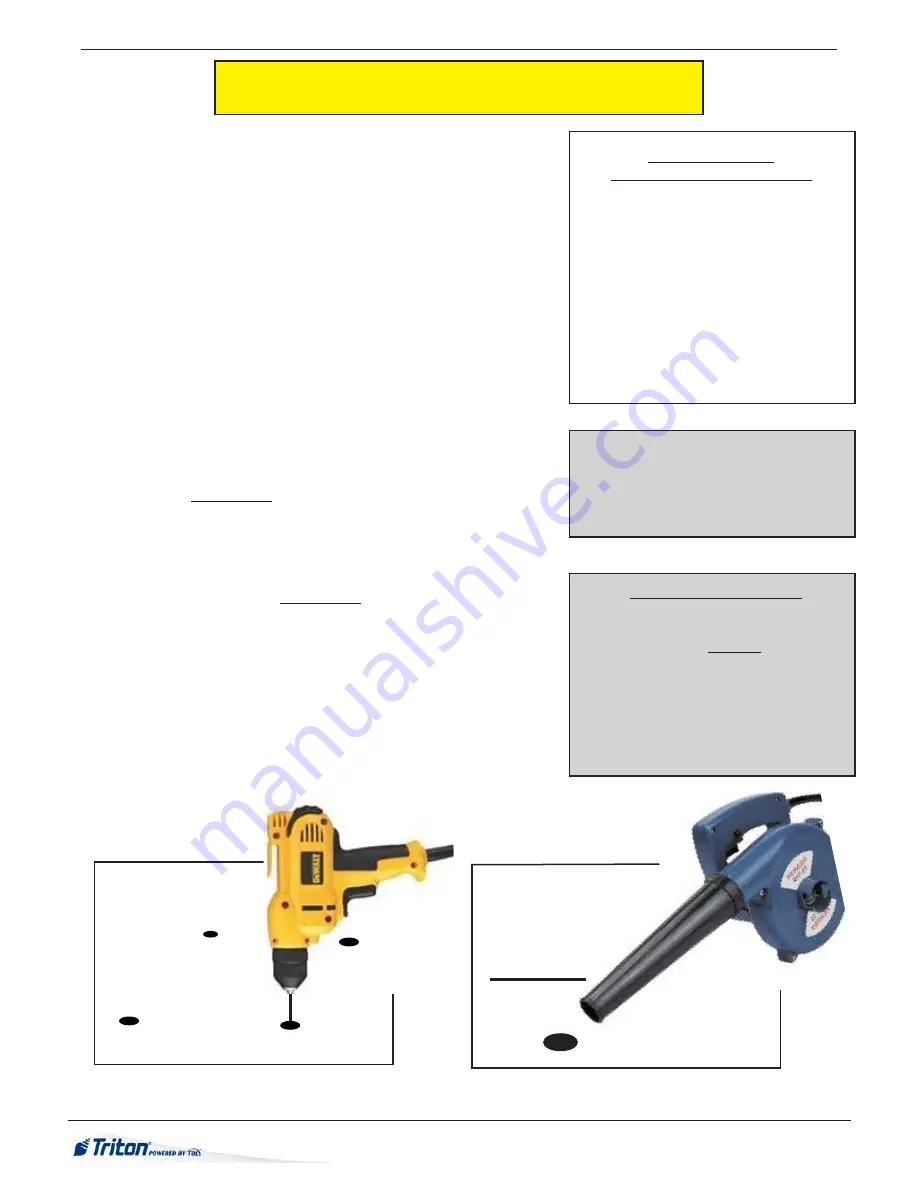

Use a 1/4” [6 mm] diameter carbide-tipped masonry bit to drill four pilot

holes at the drilling points marked in the previous step. Drill the pilot holes

approximately 1/2” [12 mm] deep into the floor. These holes will help guide

the masonry bit that will be used to drill the anchor-bolt holes in the next step.

3.

Standard anchors:

Use a

1/2” [13mm]

diameter carbide-tipped masonry bit

to drill four holes at least

2-3/4” [70mm]

deep into the floor. Be sure to take

into account the depth of any floor covering, such as tile or vinyl when gauging

the depth of the anchor holes.

Make sure the holes are drilled at least 2- 3/4”

[70mm] into the concrete floor.

3a.

Chemical anchors:

Use a

9/16” [15mm]

diameter carbide-tipped masonry

bit to drill four holes at least

4-1/2” [115mm]

deep into the floor. Be sure to

take into account the depth of any floor covering, such as tile or vinyl when

gauging the depth of the anchor holes.

Make sure the holes are drilled at least

4- 1/2-inches [115mm] into the concrete floor.

TOOL USE/SAFETY

Observe ALL safety precautions for operat-

ing hand and power tools! Wear eye and ear

protection while operating the electric drill!

m

ark

/d

rill

m

ountinG

H

oles

4.

Hole Diameter:

Ensure the holes drilled are not too large in diameter. Test fit

the anchor bolts by hand. They should require hammering, accomplished in

a later step, and not fall into the hole. Its easier to drill the holes larger now if

necessary, than have to move the cabinet and redrill later because they are too

big.

DO NOT

be tempted to install the anchors now. It is

VERY

difficult to

position the terminal onto the anchors because of the weight.

5.

Use a portable vacuum cleaner or blower to remove dust or debris that may

have fallen into the holes during the drilling process.

Blow or vacuum out dust/debris.

Figure 2

Drill 9/16” anc

hor hole

s with carbide-tipped bit.

Figure 1