114-13233

Rev B

10

of 13

Figure 10

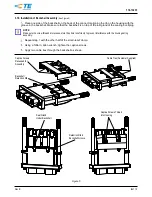

3.15.

Placement

CAUTION

Connectors should be handled only by the housing to avoid deformation, contamination, or damage to the contacts.

When placing connectors on the pc board, make sure that the contacts are aligned and started into the

matching holes before seating the connector onto the pc board.

3.16.

Soldering Connectors

The PC Board Quadrax Connector can be soldered with wave, vapor phase, or infrared reflow processes,

provided the temperatures and exposure time are within the ranges specified in Figure 11. TE recommends the

use of SN60 or SN62 solder for the connectors. Refer to Paragraph 2.4 for instructional material that is

available for establishing soldering guidelines.

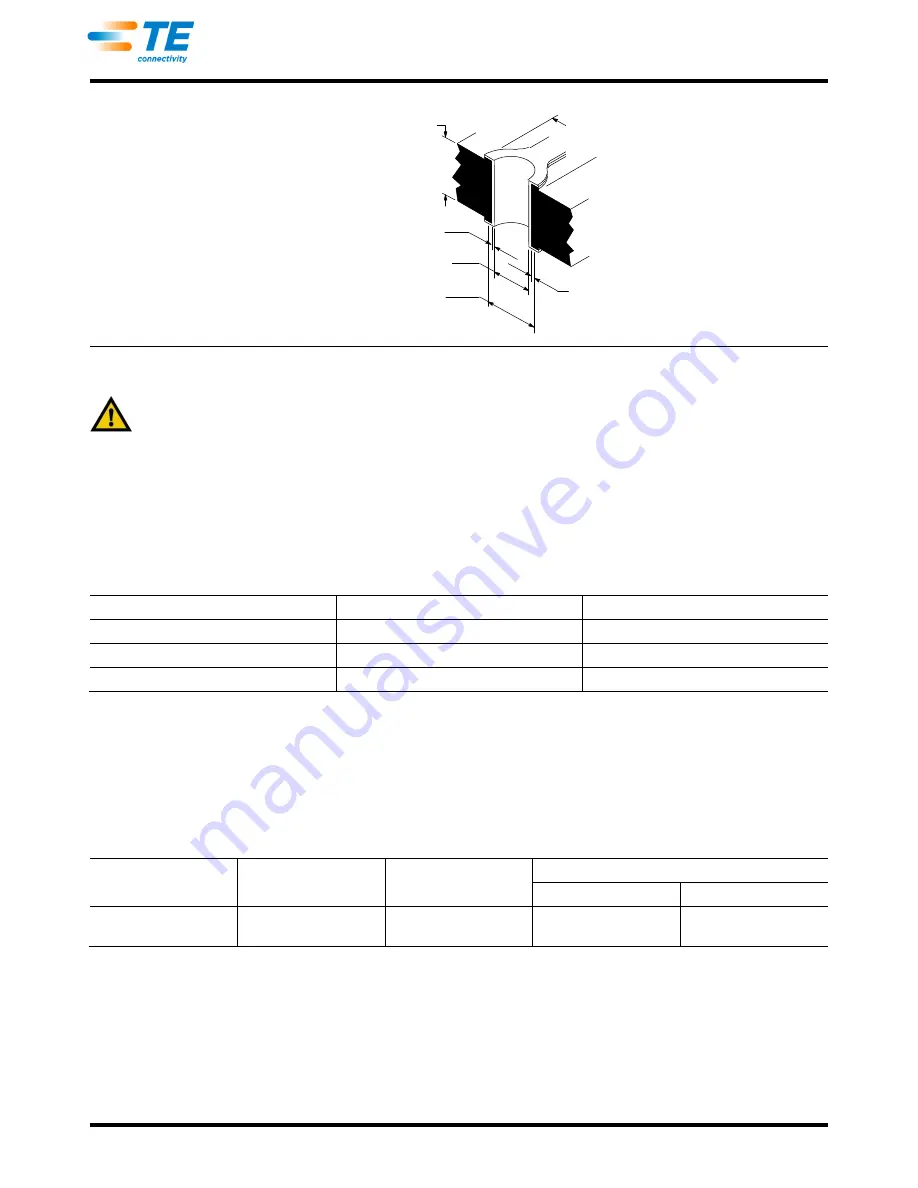

SOLDERING PROCESS

TEMPERATURE

TIME (At Max Temperature)

Wave

260°C [500°F] (Wave Temperature)

5 Seconds

Vapor Phase

215

°

C [419

°

F]

5 Minutes

Infrared Reflow

230

°

C [446

°

F]

5 Minutes

Figure 11

A.

Flux Selection

Contact solder tines must be fluxed prior to soldering with a mildly active, rosin base flux. Selection of the

flux will depend on the type of pc board and other components mounted on the board. Additionally, the

flux must be compatible with the wave solder line, manufacturing, health, and safety requirements. Call

the Product Information phone number at the bottom of page 1 for consideration of other types of flux.

Some fluxes that are compatible with these connectors are provided in Figure 12.

FLUX TYPE

ACTIVITY

RESIDUE

COMMERCIAL DESIGNATION

KESTER

ALPHA

Type RMA

(Mildly Activated)

Mild

Noncorrosive

186

611

Figure 12

B.

Cleaning

After soldering, removal of fluxes, residues, and activators is necessary. Consult with the supplier of the

solder and flux for recommended cleaning solvents. The following is a listing of common cleaning solvents

that will not affect the connectors for the time and temperature specified. See Figure 13.

KESTER AND ALPHA are trademarks of their respective companies.

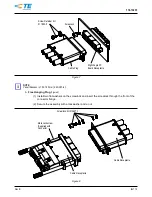

Board Thickness 1.60 [.063] Nominal

Pad Diameter (As

Required)

Tin or Tin/Lead Thickness (As Required)

Dia of Finished Hole After Plating 1.07 [.040] Min●

Drilled Hole Diameter (As Required)

Copper Thickness (As Required) (Maximum

Hardness of Copper to be 150 Knoop)

●Ground Legs 1.65 [.065] Min.