408-35160

Rev

A

4

of 8

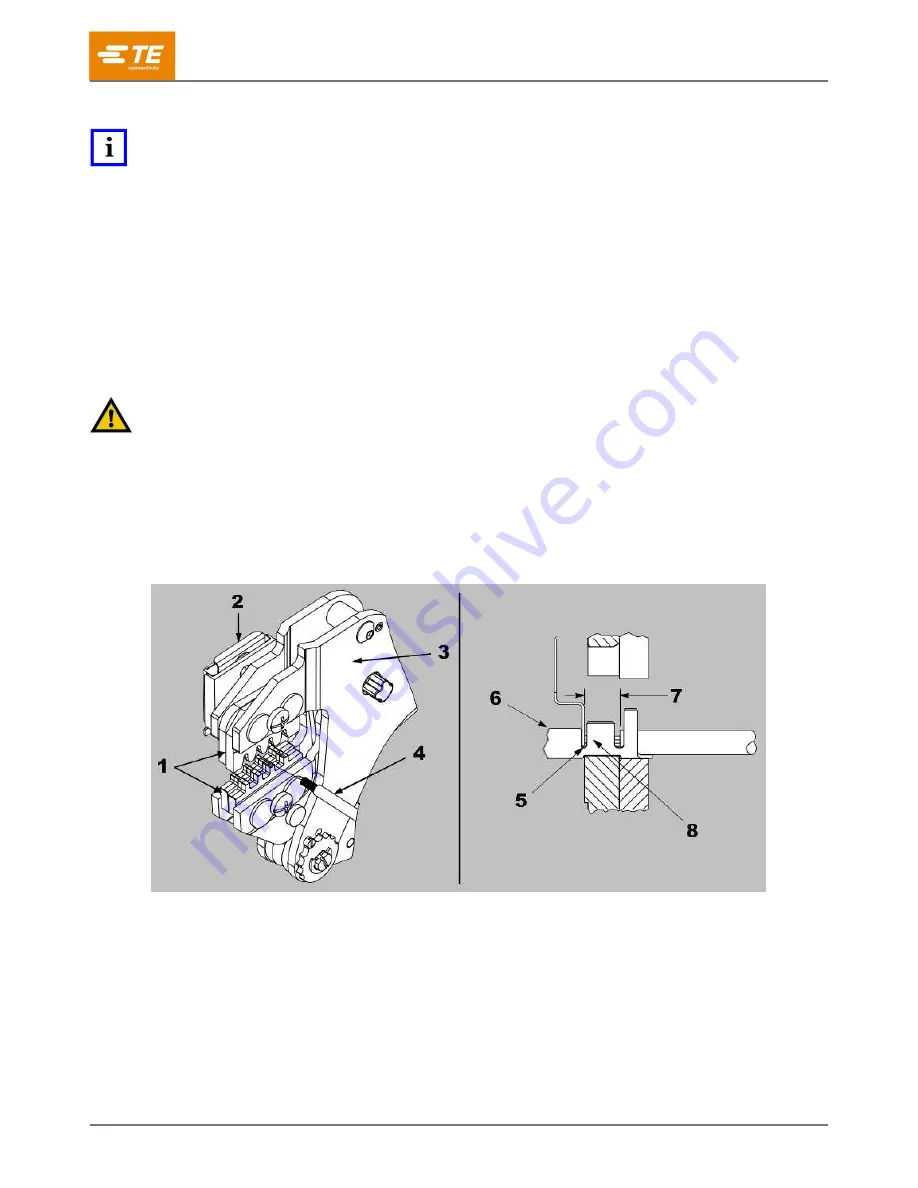

4.

CRIMPING PROCEDURE

NOTE

The tool is provided with a crimp adjustment feature. Initially, the crimp height should be verified as specified in Figure 4. Refer

to Section 6, INSPECTING THE CRIMP HEIGHT, and Section 7, ADJUSTING THE RATCHET, to verify crimp height before

using the tool to crimp contacts and wire sizes.

Refer to Table 1 and select wire of the specified size and insulation diameter. Strip the wire to the length

indicated.

Do not nick or cut wire strands.

Select an applicable contact and identify the appropriate crimp

section according to the wire size markings on the tool. Refer to Figure 2 and proceed as follows:

1. Hold the tool so that the back (wire side) is facing you. Squeeze the tool handles together and allow

them to open fully.

2. Holding the contact by the mating end, insert the contact through the front of the tool and into the

appropriate crimp section.

3. Position the contact so that the U of the wire barrel faces the top of the tool. Place the contact up into

the nest so that the wire barrel is against the spring-loaded locator.

CAUTION

Make sure that both sides of the wire barrel are started evenly into the crimping section.

Do not

attempt to crimp an

improperly positioned contact.

4. Close the handles of the tool until the contact is lightly held by the die set, but is not deformed to the

point where the wire cannot enter freely.

5. Insert the wire into the crimp barrel of the contact until it butts against the spring-loaded locator.

6. While holding the wire in place, fully cycle the tool until the ratchet releases and allows the handle to

open.

Figure 2: Crimping

1

Die assembly (for reference only)

5

Locator in wire stop slot

2

Locator

6

Contact (typical)

3

Back of tool (wire side)

7

Strip length

4

Wire

8

Wire inserted to stop