408-35137

Rev

B

5

of 6

4.

INSPECTING THE CRIMP HEIGHT

Crimp height inspection is performed using a micrometer with a modified anvil, commonly referred to as a

crimp-height comparator. TE Connectivity does not manufacture or market crimp height comparators. Detailed

information on obtaining and using crimp-height comparators can be found in instruction sheet

1. Refer to Table 1 and select a wire (maximum size) for each crimp section listed.

2. Refer to section 3, CRIMPING, and crimp the contacts accordingly.

3. Using a crimp height comparator, measure the wire barrel crimp height. If the crimp height conforms to

the value listed in Table 3, the tool is considered dimensionally correct.

CAUTION

Do not use damaged product. If a damaged contact is evident, replace it. Do not re-terminate contacts.

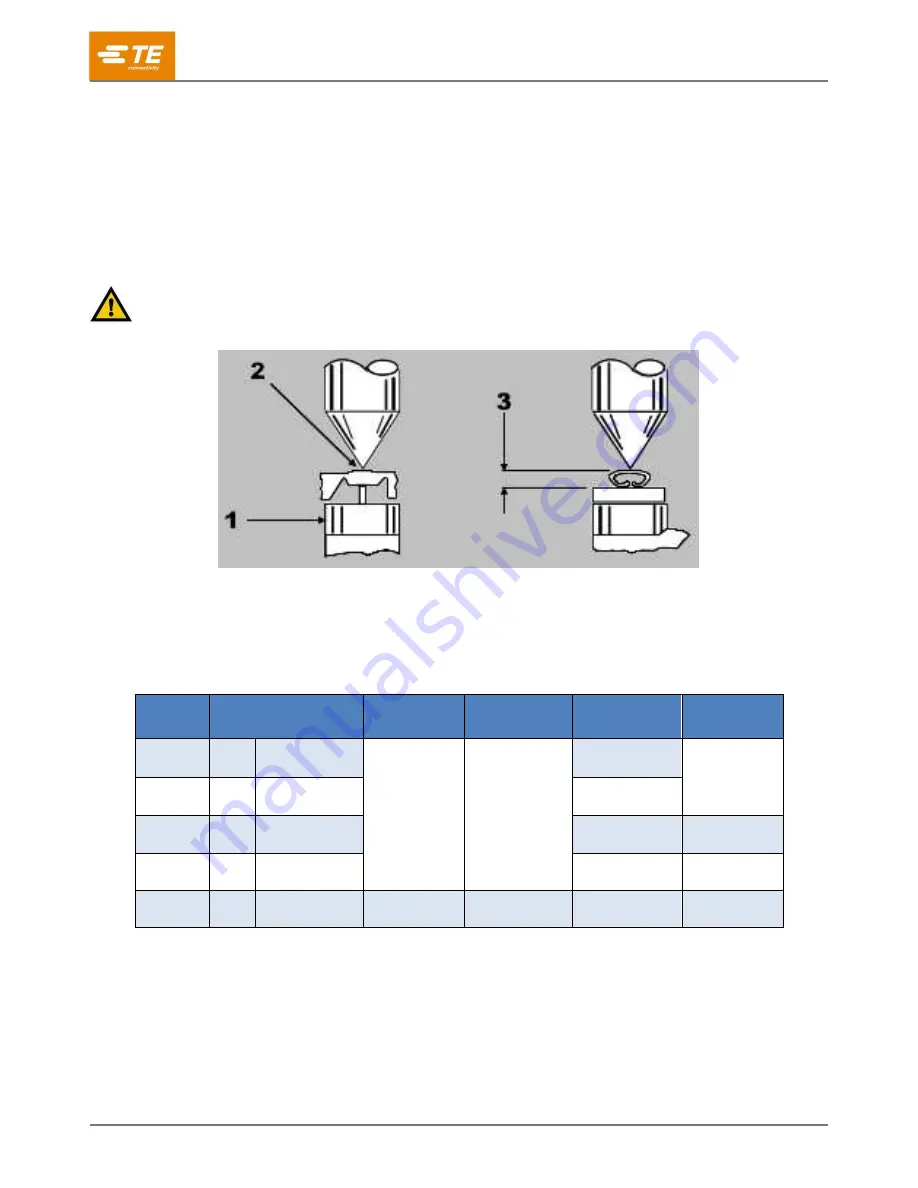

Figure 4: Crimp height

1

Modified anvil

2

Position point on center of wire barrel opposite seam

3

Crimp height (see Table 3)

Table 3: Crimp height specifications

Wire

type

Insulation selector

Wire crimp

height

Wire crimp

width

Insulation

crimp height

Insulation

crimp width

10 TXL

1

3.81-4.32

[.150-.170]

2.44-2.59

[.096-.102]

3.56-3.71

[.140-.146]

3.68-4.19

[.145-.165]

4.11-4.42

[.162-.174]

10 GXL

2

4.06-4.57

[.160-.180]

4.27-4.52

[.168-.178]

10 SXL

3

4.32-5.21

[.170-.205]

4.32-4.83

[.170-.190]

4.17-4.47

[.164-.176]

5.0 mm

2

2

4.06-4.57

[.160-.180]

3.68-4.19

[.145-.165]

4.11-4.42

[.162-.174]

6.0 mm

2

3

4.32-5.21

[.170-.205]

2.49-2.64

[.098-.104]

3.61-3.76

[.142-.148]

4.44-4.95

[.175-.195]

4.17-4.47

[.164-.176]