Page 42 / 101 ECOC: EGC0 ; LOC: AI

528050-1

412-18876 Rev. G

4.4

Hazardous Areas

1.

Hazardous Area: Area of interchangeable crimping dies

Person at risk:

Operator

Type of Hazard:

Hand Injuries

2.

Hazardous Area: Opened Machine

Person at risk:

Installation Engineer

Type of Hazard:

Direct or indirect contact with movable parts of the machine,

Hand injuries (cuts from sharp edges)

Hand injuries (risk of crushing)

4.5

Safety Precautions

Please observe the national reglementations according to the minimum age of the personnel operating

the Pneum. Parallel Crimp Machine AT-SC. Allowing younger persons access to the machine is strictly

prohibited.

O

Exercise caution at any time when the Pneum. Parallel Crimp Machine AT-SC is switched on.

O

Operate the Pneum. Parallel Crimp Machine AT-SC in a dry and dust free environment only.

The crimp machine is only allowed to be used when it is in complete functional condition.

O

When working with the Pneum. Parallel Crimp Machine AT-SC, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the Pneum. Parallel Crimp Machine AT-SC.

O

Prior to starting up the Pneum. Parallel Crimp Machine AT-SC, make sure it is firmly positioned

on a sturdy stand or bench to prevent it from tipping over.

O

Disconnect the Pneum. Parallel Crimp Machine AT-SC from the air supply before attempting

any maintenance work. Due to the risk of hand or finger injury, never try to reach into the

machine before having assured that the machine is disconnected from the air supply.

O

Check the release button before starting the work on the crimp machine.

O

Do not modify the Pneum. Parallel Crimp Machine AT-SC nor use it for any purpose for which it

was not intended.

O

Do not operate the Pneum. Parallel Crimp Machine AT-SC until you have studied and fully

understood all the instructions described in this instruction manual.

O

In cases of a machine malfunction, production must be stopped and the malfunction must be

fixed before continuing work with the machine.

O

In the case of imminent danger immediately press the release button. The release button must

be within the direct reach of the operator. It must not be covered.

O

Maintenance work may be performed only by authorized and properly trained personnel.

O

The Pneum. Parallel Crimp Machine AT-SC has to carry handles for the transport by hand.

Wear safety shoes during the transport of the machine.

O

The Pneum. Parallel Crimp Machine AT-SC is not allowed to be used without a mounted

adapter.

O

For maintenance work wear adequate protective gloves and safety glasses.

O

Only one person is allowed to work on or with the machine.

O

Only trained personal are allowed to work on or with the machine.

O

It is only allowed to work with the specified working pressure.

Summary of Contents for AT-SC

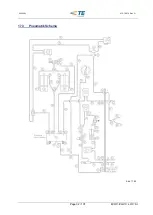

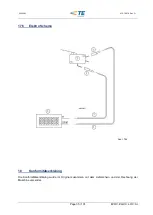

Page 32: ...Page 32 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Pneumatik Schema Abb 17 02...

Page 65: ...Page 65 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Pneumatic Diagram Fig 17 02...

Page 98: ...Page 98 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Sch ma Pneumatique Fig 17 02...