Page 46 / 101 ECOC: EGC0 ; LOC: AI

528050-1

412-18876 Rev. G

7.2

Installation

INFORMATION:

To reduce production noise or vibration the machine can be placed on an insulating

rubber mat.

ATTENTION!

Position the Pneum. Parallel Crimp Machine AT-SC

on a flat surface and assure the

stability of the machine. Ensure that the table or bench is stable enough to support

the machine in normal use.

Assure an appropriate table height. The table height is depending on the position of

the operator (work in sitting or standing position) according to prEN 894-4:2004,

Table A.1.

The crimping machine does not have its own light source. Assure an appropriate

illumination of the working place. (EN 1837:1999

– chapter 4.2: “The general value

of illumination has to be 500 lx [...]")

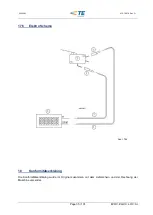

Place the double foot petal on the floor. No other place is allowed.

INFORMATION:

When the operator is positioned in the front of the machine the pedal should be placed

in a comfortable position. The pedal should be placed on an anti slip rubber mat. The

double foot pedal must be movable, so that the operator has the possibility to change

his position for ergonomic and production needs.

ATTENTION!

Place the tubes on the floor so that they do not cause a trip hazard.

Do not lay the double foot pedal in aisles or walk ways.

Assure free access to the operating elements of the machine, especially the double

foot pedal and the release button.

During transport and installation of the machine wear suitable safety shoes.

Summary of Contents for AT-SC

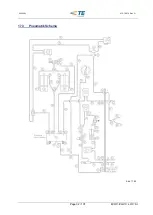

Page 32: ...Page 32 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Pneumatik Schema Abb 17 02...

Page 65: ...Page 65 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Pneumatic Diagram Fig 17 02...

Page 98: ...Page 98 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Sch ma Pneumatique Fig 17 02...