Page 52 / 101 ECOC: EGC0 ; LOC: AI

528050-1

412-18876 Rev. G

- Disconnect air supply.

-

Choose the correct die-set and remove special

screws from the die (Fig. 9.05).

-

Place the lower and upper die onto the die-

holder, replace and tighten the screws

INFORMATION:

Control the right position of the die halves!

- Connect air supply.

9.3

Push-in device (P/N 528052-1) (Optional Acceccesory for WDT Adapter)

DANGER!

Due to the risk of hand or finger injury, never try to reach into the machine before

having assured that the machine is disconnected from the air supply. Disconnect the

air supply before changing the adapter or the dies.

CAUTION!

The crimp machine is only allowed to be used with mounted adapter and die set.

The crimp machine is only allowed to be used when it is in complete functional

condition.

When working with the Pneum. Parallel Crimp Machine AT-SC, do not wear loose

clothing, jewellery or long, loose hair that can get caught in the Pneum. Parallel

Crimp Machine AT-SC.

Work with caution.

Only trained personal are allowed to work on or with the machine.

- Disconnect air supply.

- Install the push-in device (Fig. 9.06) onto the

lower die holder either on the right or left side

and tighten mounting screw.

Fig. 9.06

Fig. 9.05

Summary of Contents for AT-SC

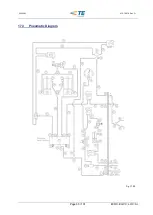

Page 32: ...Page 32 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Pneumatik Schema Abb 17 02...

Page 65: ...Page 65 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Pneumatic Diagram Fig 17 02...

Page 98: ...Page 98 101 ECOC EGC0 LOC AI 528050 1 412 18876 Rev G 17 3 Sch ma Pneumatique Fig 17 02...