114-151049

Rev A

9

of 11

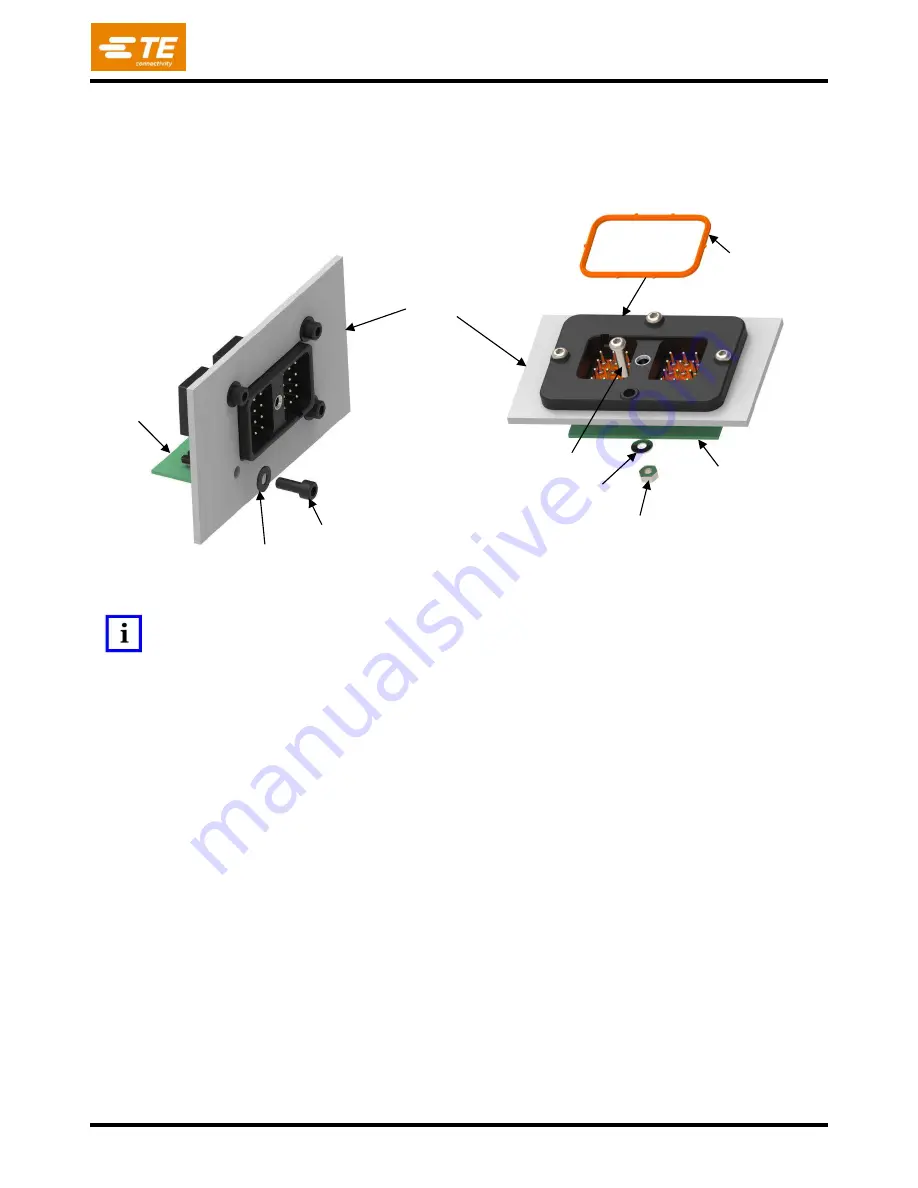

3.11. Panel Mounting

Insert the header through the panel cutout then secure the header using 10-32 hardware (M5 for C023

and CG01 modifications). DRC10-24P requires 0510-014-2406 flange seal (sold separately). Mounting

hardware (i.e. screw, washer, nut) are customer supplied. Screw length depend on application.

Recommended torque: 2.26-2.83 [20-25 in-lbf].

Recommended panel thickness is 6.25 [.250] max.

Note:

1)

Mounting torque not to damage connector or panel

3.12. Replacement and Repair

Damaged or defective header must not be used. It may be removed from the PCB by normal desoldering

methods and replaced with a new header.

4. QUALIFICATION

Refer to product specification

for qualification and approved agency.

5. TOOLING

No special tooling is required for hand placement of the header onto the PCB or installation of the mating

plug connector.

PCB

Washer 4X

Screw 4X

PCB

Screw 4X

Washer 4X

Nut 4X

Panel

0510-014-2406