408-78067

Rev A

3

of 4

4.

HEADER CONNECTOR

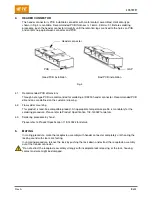

The header connector is PCB installable connector with metal contact assembled. Horizontal type

shown in Fig.4 is available. Recommended PCB thickness is 1.6mm~2.4mm±0.1. Before soldering

procedure, push the header connector straightly until the retention legs are fixed to the holes on PCB

and confirm no gap between connector and PCB.

Fig. 4

4.1.

Recommended PCB dimensions

Through-hole type PCB is recommended for soldering of D5900 header connector. Recommended PCB

dimensions are defined on the customer drawing.

4.2.

Flow solder mounting

This product is lead-free compatible product. An appropriate temperature profile is mandatory for the

soldering procedure. Please refer to Product Specification 118-140022 for details.

4.3.

Soldering procedure by hand

Please refer to Product Specification 118-140022 for details.

5.

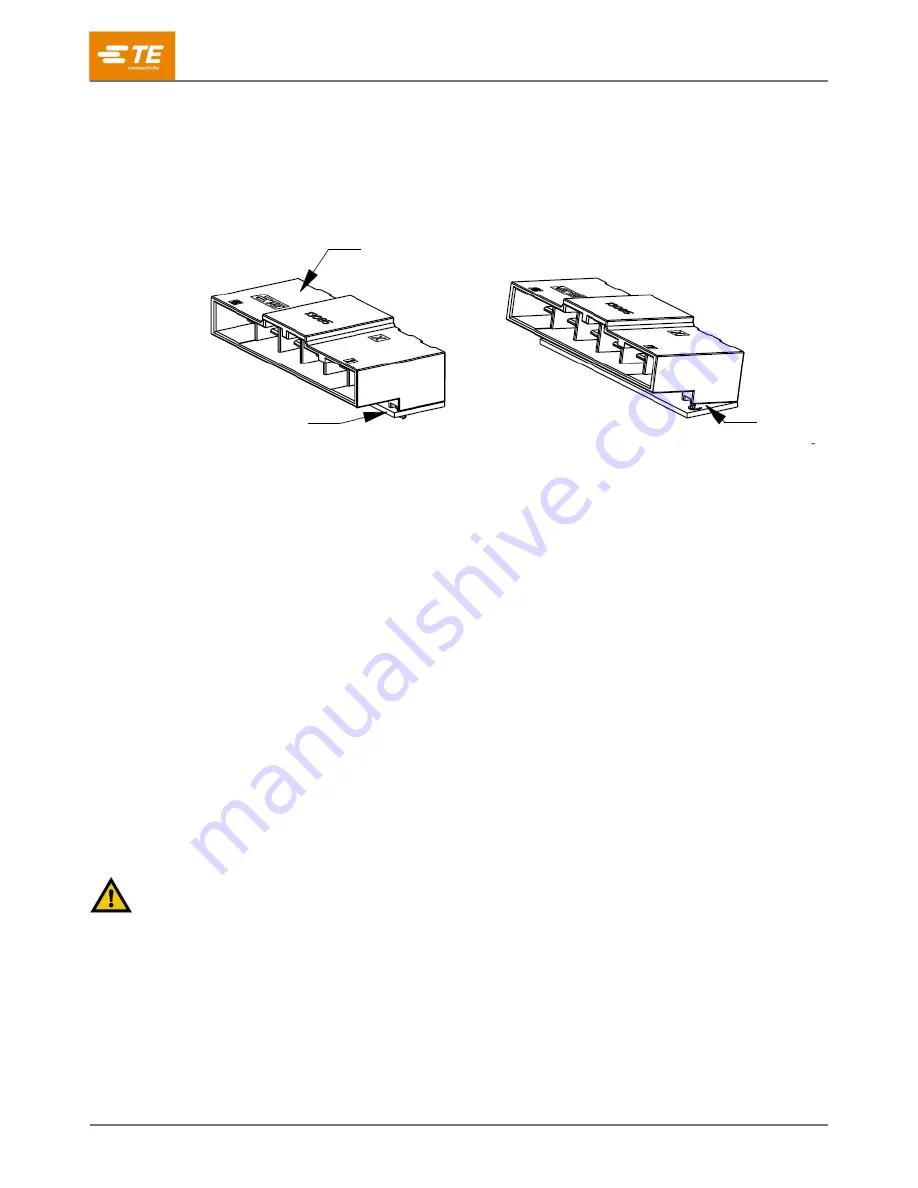

MATING

In mating procedure, mate the receptacle assembly with header connector completely until hearing the

locking sound with clear click feeling.

In unmating procedure, release the lock by pushing the lock down and extract the receptacle assembly

out of the header connector.

*Do not extract the receptacle assembly strongly with incomplete lock releasing, or the lock, housing,

contact and wire might be damaged.

Header connector

PCB

Good PCB installation

Bad PCB installation

GAP