408-35328

Rev

A

3

of 7

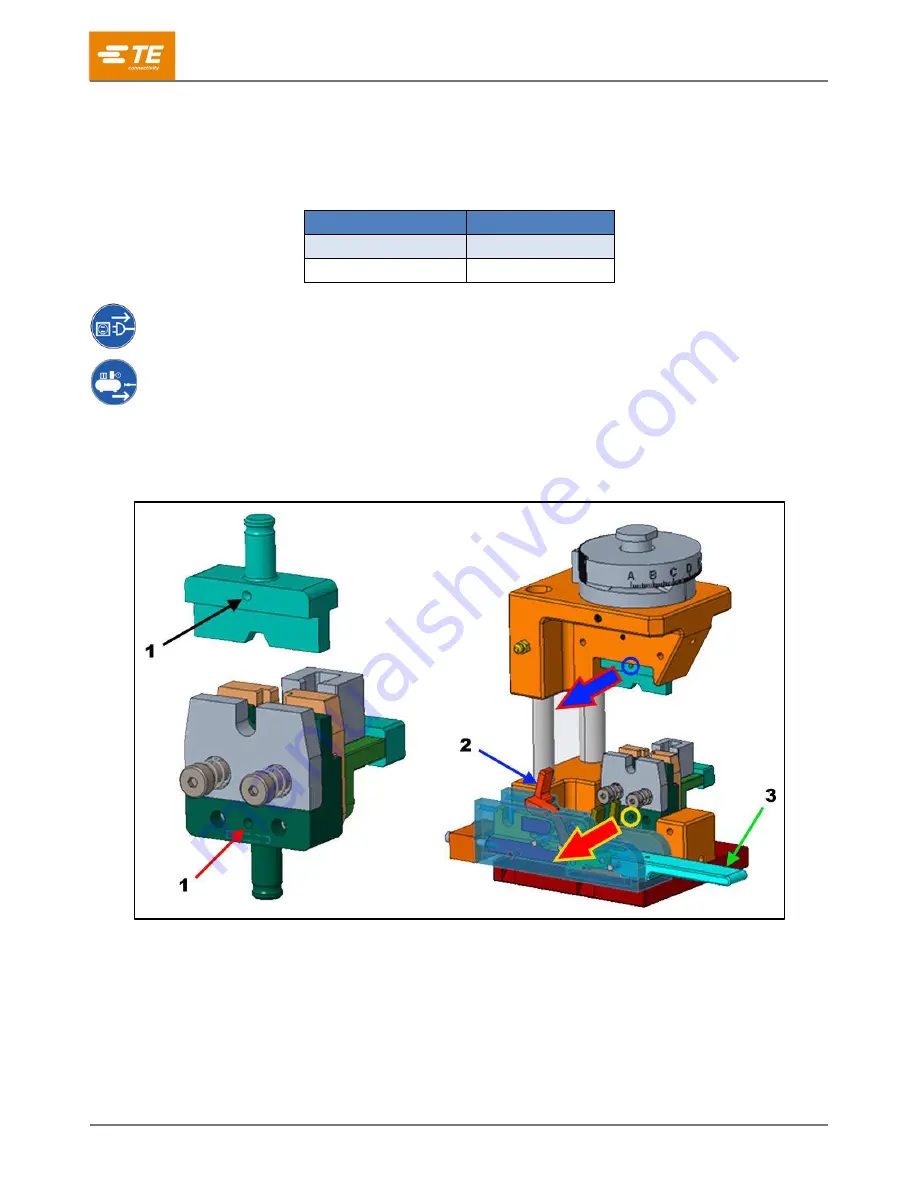

3 Installing the die set and locator assembly

For information concerning die installation, removal, and general performance of each modular tool holder,

refer to the applicable 408 series instruction sheet packaged with the tool holder (Table 2).

Table 2: Instruction sheets

Modular tool holder

Instruction sheet

2305470-1

2326378-1

Disconnect electrical power before performing maintenance or repair on this equipment.

Disconnect air supply before performing maintenance or repair on this equipment.

To achieve proper orientation of the dies during installation, ensure that the alignment dots are facing in the

direction of the wire clamp on the modular tool holder (Figure 3).

Figure 3: Alignment dots

1

Alignment dots

2

Wire clamp

3

Lever