408-35328

Rev

A

6

of 7

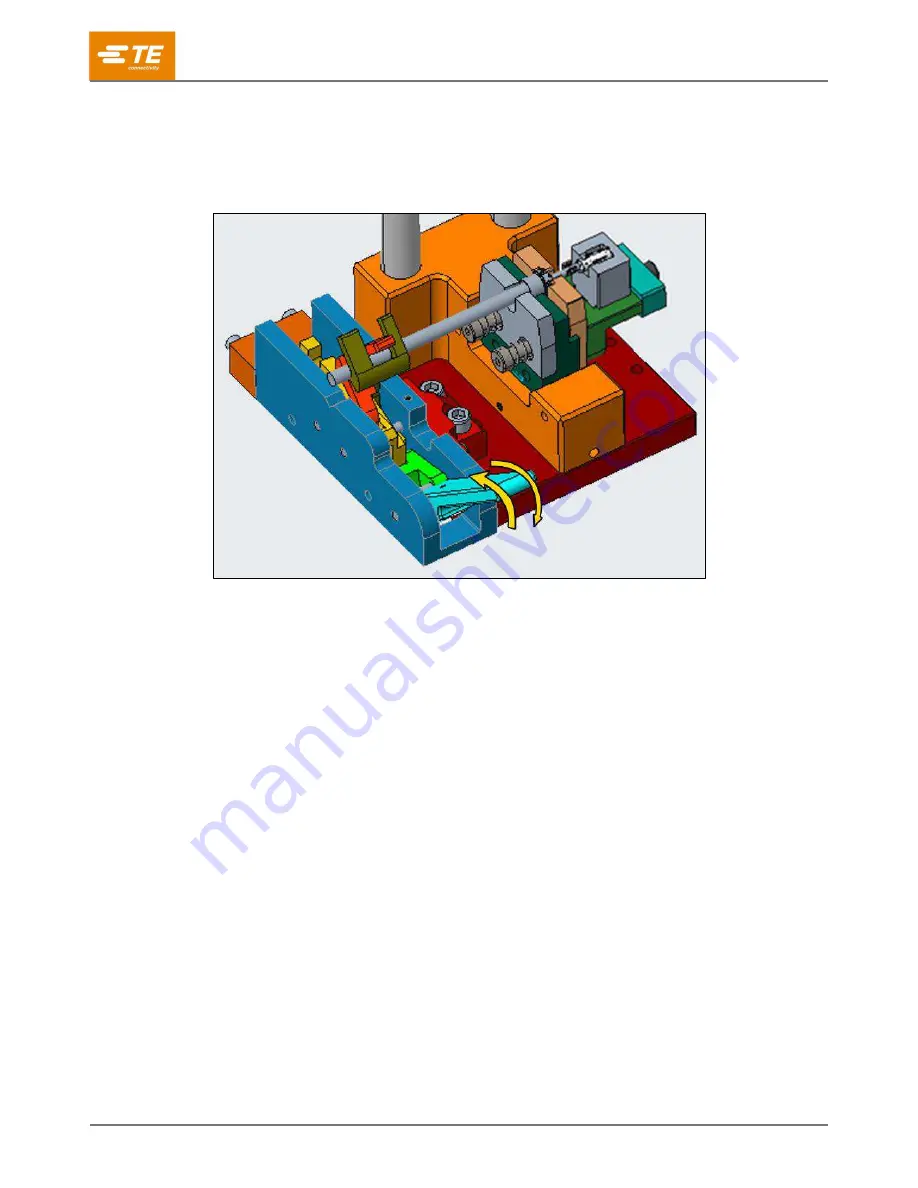

5. Close the wire clamp to hold the wire in place.

6. Cycle the terminator to complete the crimp.

7. Open the wire clamp to remove the crimped assembly from the tooling.

Figure 6: Closing and opening the wire clamp

5 Inspecting the crimp

For crimp inspection information, refer to the 114 series application specification listed in Table 1 for the ferrule

being crimped.

6 Maintenance and inspection

Each die assembly is inspected before shipment. When it arrives at your facility, inspect it immediately to

ensure that it was not damaged during shipping.

6.1 Daily maintenance

Make each operator aware of (and responsible for) the following daily maintenance requirements:

Remove dust, moisture, and other contaminants with a clean, soft brush or soft, lint-free cloth.

Do not

use objects that could damage the dies or tool.

When the dies are not in use, store them in a clean, dry area.

6.2 Periodic inspection

Regular inspections should be performed by quality control personnel. A record of scheduled inspections

should remain with the dies or be supplied to personnel responsible for the dies. Perform at least one

inspection per month. Base your inspection frequency on the amount of use, ambient working conditions,

operator training and skill, and established company standards. Perform the inspection as follows:

1. Remove all contaminants with a clean, soft brush or soft, lint-free cloth. Do not use objects that could

damage the dies.

2. Inspect the crimp area for flattened, chipped, cracked, worn, or broken areas.

3.

If damage or abnormal wear is evident, replace the tool or dies. Refer to section

Error! Reference s

ource not found.

, Error! Reference source not found..