408- 9357

3

of 5

Rev

E

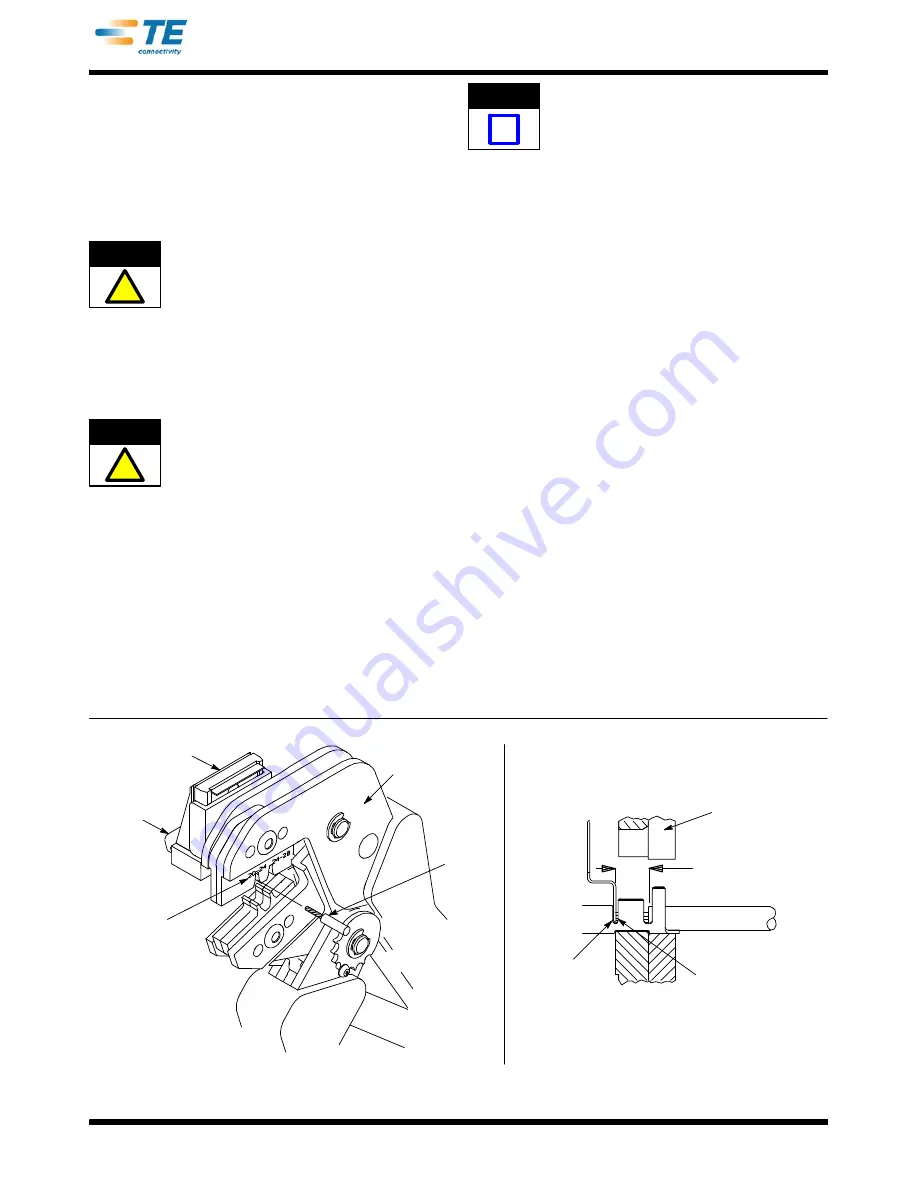

1. Hold the tool so that the front (locator side) is

facing you. Squeeze tool handles together and

allow them to open fully.

2. Insert the contact—mating end first—into the

hole in the locator which corresponds with the

appropriate crimping chamber. Make sure that the

open “U” of the wire barrel and insulation barrel

face the stationary jaw.

Do NOT attempt to close the tool handles when

locator contact retainer is between the dies.

Damage to the tool jaws or locator may result.

3. Slide the locator contact retainer out from

between the dies (spring tension will pull the

locator down). Make sure that the wire stop enters

the contact wire stop slot between the wire barrel

and contact shoulder. Release contact retainer.

Make sure that both sides of the contact

insulation barrel are started evenly into the

crimping chamber. Do NOT attempt to crimp an

improperly positioned contact.

4. Hold the contact in position, and squeeze the

tool handles together until ratchet engages

sufficiently to hold the contact in position. Do NOT

deform insulation barrel or wire barrel.

5. Insert stripped wire into contact insulation and

wire barrels until it is butted against the wire stop,

as shown in Figure 3.

6. Holding the wire in place, squeeze tool handles

together until ratchet releases. Allow tool handles

to open and remove crimped contact.

The crimped contact may stick in the crimping

area, but can be removed by pushing downward

on the top of the locator (see Figure 3).

7. Check the contact crimp height as described in

Section 5, CRIMP HEIGHT INSPECTION. If

necessary, adjust the crimp height as described in

Section 6, CRIMP HEIGHT ADJUSTMENT.

5. CRIMP HEIGHT INSPECTION

Crimp height inspection is performed through the use

of a micrometer with a modified anvil, commonly

referred to as a crimp--height comparator. TE does

not manufacture or market crimp--height comparators.

Detailed information on obtaining and using

crimp--height comparators can be found in instruction

sheet 408--7424.

Proceed as follows:

1. Refer to Figure 4 and select the

maximum

size

wire for the crimping chamber.

2. Refer to Section 3, CRIMPING PROCEDURE,

and crimp the contact accordingly.

3. Using a crimp height comparator, measure the

wire barrel crimp height as shown in Figure 4. If the

crimp height conforms to that shown, the tool is

considered dimensionally correct. If not, the tool

must be adjusted. Refer to Section 6, CRIMP

HEIGHT ADJUSTMENT.

Figure 3

Wire Strip Length

Locator in

Contact Wire

Stop Slot

Wire Inserted to

Locator Wire Stop

Tool Stationary

Jaw

Wire

Tool Wire

Size Markings

Back of Tool

(Wire Side)

Contact

Retainer

Locator

CAUTION

!

CAUTION

!

NOTE

i